Characteristics and advantages of epoxy coating

Corrosion is one of the major issues affecting the durability and performance of metal structures. The use of epoxy coatings is seen as a solution to corrosion due to their excellent corrosion resistance. In this article, we will discuss the corrosion resistance properties, benefits, characteristics, and applications of epoxy coatings.

What is the epoxy coating?

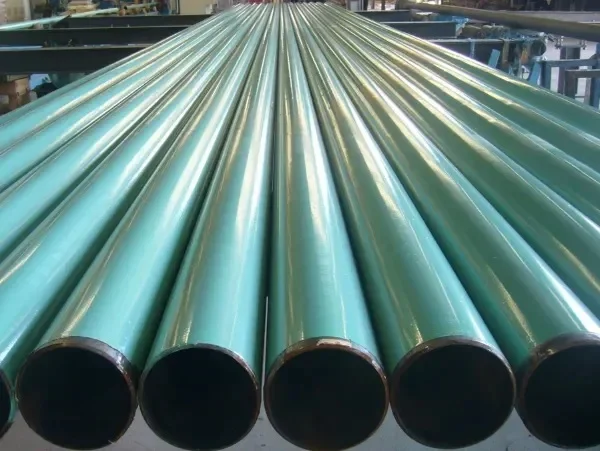

Epoxy coatings are thermosetting polymers widely used to protect metal structures from corrosion. The coating forms a tough, hard, and chemically resistant layer on metal substrates, providing excellent adhesion.

Performance and advantages of epoxy coatings:

Epoxy coatings offer several advantages that make them an ideal solution for corrosion protection:

1. High corrosion resistance: Epoxy resin coating has high corrosion resistance and is suitable for harsh environments.

2. Chemical resistance: Epoxy resin coatings are resistant to many chemicals such as acids, alkalis, solvents, etc., ensuring that the metal surface is protected.

3. Durability: Epoxy coating provides a hard surface which increases durability making it ideal for industrial applications.

4. Adhesion: Epoxy coatings have excellent adhesion and are ideal for surfaces that require a strong bond.

5. Easy to clean: Epoxy coatings are easy to clean and ideal for use in various industries such as food and beverages.

6. Aesthetic Value: Epoxy coatings come in a variety of colors and can enhance the appearance of metal surfaces.

Types of epoxy coatings:

There are several types of epoxy coatings, including:

1. 100% solids epoxy coating

2. Waterborne epoxy coating

3. Solvent based epoxy coating

4. Self-priming epoxy coating

5. High-build epoxy coating

Application of epoxy coatings:

Epoxy coatings are used in a wide variety of industries including:

1. Marine Industry: Epoxy coatings are ideal for protecting ships, offshore platforms, and other marine structures.

2. Oil and Gas Industry: Epoxy coatings provide protection for storage tanks, pipelines, and other metal structures used in industry.

3. Food and beverage industry: Epoxy resin coatings are used to protect surfaces in contact with food to ensure safety and hygiene.

4. Automobile industry: Epoxy resin coatings are used to protect the chassis, wheels, and body of vehicles from corrosion.

5. Construction industry: Epoxy coatings are used to protect concrete floors, walls, and other structural components from damage from chemicals, abrasion, and abrasion.Section

The use of epoxy coatings offers significant benefits in protecting metal structures from corrosion. Epoxy coatings are used in a variety of industries due to their high resistance, durability, chemical resistance, and ease of maintenance. Understanding the different types of epoxy coatings and their application is critical to selecting the most suitable coating for desired results.

Cangzhou Shenlong Pipe has a lot of experience in the design and production of water treatment pipelines, and can produce various specifications of steel pipes and fittings according to the project requirements, and do anti-corrosion treatment.

How to Distinguish the Quality of Epoxy Coated Steel Pipes?

What does epoxy-coated steel pipe storage pay attention to?

What do you need to pay attention to when installing epoxy coated steel pipe?