Coated plastic steel pipe for coal mines

The presence of biogas (methane, etc.) is often associated with coal seams. Methane gas is liable to cause explosion accidents. Therefore, when working in a closed space, it is necessary to monitor the concentration of biogas frequently. If there is a certain concentration of dust in the gas, it can also cause an explosion due to Mars. The dust volume is small, but the relative proportion of the surface is large. If there is enough oxygen in the surrounding air, it will be very sensitive to the combustion reaction. And biogas itself is harmless to humans, but sometimes accompanied by toxic gases such as carbon monoxide. If a large amount of methane gas is ejected at a time, the likelihood of gas explosion usually increases rapidly.

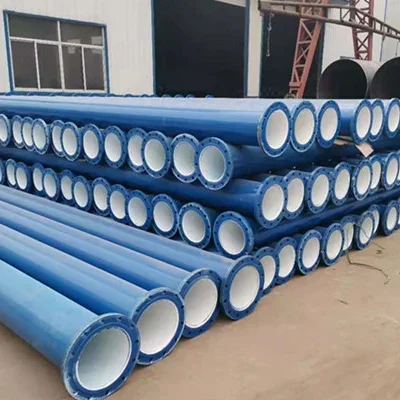

How to control these gases and deliver oxygen down the well to provide oxygen for underground mining personnel is the main reason to avoid accidents in coal mining. Fuzong coal mine coated steel pipe, using flame retardant, antistatic special powder material. The foundation of coated plastic steel pipe in coal mine is antistatic, which greatly reduces the accident rate.

Product Features:

1, coal mine coated plastic steel pipe superior antistatic and flame retardant performance

2. Coal mine coated plastic steel pipe has high mechanical strength

3, coal mine coated plastic steel pipe corrosion resistance, anti-aging, long service life

4, coal mine coated plastic steel pipe fluid resistance is small, cost-effective

5, coal mine with a variety of plastic steel pipe connection, convenient and reliable

Application of coal coated plastic steel pipe in coal mine: underground water supply and drainage, fire sprinkling, underground grouting, positive and negative pressure ventilation and gas extraction, etc

Cangzhou shenlong pipe manufacturing co., ltd. Is engaged in oil, gas, water, coal slurry mixing medium steel pipeline coating operations, anti-corrosion, insulation, piping is set in a body's specialized pipeline engineering precast construction enterprises, products used in an oil pipeline, chemical piping, electrical, pipe, gas pipe, heat pipes, sewage pipes, etc. Anti-corrosion processing of straight pipe and bend pipe DN40-3000 three-layer structure polyolefin (PE, PP, TPEP,3LPE) steel pipe coated with anti-corrosion, DN40-3800 steel hot stewed bend pipe and pipe fittings coated with FBE, epoxy resin coating anti-corrosion, DN40-3800 steel pipe inner wall resistance reduction, solvent-free epoxy steel pipe, epoxy paint anti-corrosion, Coated plastic steel pipe, dip plastic steel pipe. Lined with plastic steel pipe PE, PO, PP, PTFE, HDPE, polymer polyethylene corrosion. The company is in strict accordance with China Petroleum and Natural Gas SY/T0413-2002, national GB/T23257-2009, German DIN 30670, American AWWA C210, and other international and domestic anti-corrosion standards.