Construction of epoxy powder anticorrosive steel pipe

Cangzhou Shenlong Pipe Manufacturing Co., Ltd. recently signed a new order to Peru project, DN500 EFW pipe, 4000 meters, FBE coating 500 microns outside, we will use about 60 days to complete this order.

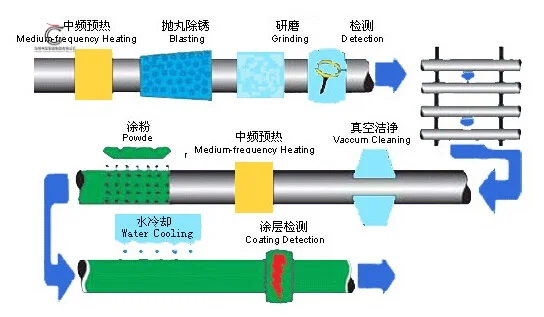

What should we pay attention to in the construction of epoxy powder anticorrosive steel pipe? Today we will introduce it again

Coating method: 40~120KV high voltage electrostatic spraying.

Recommended film thickness: 300~400um for normal grade and 400~500um for reinforcement grade.

Theoretical dosage: general grade 0.42~0.56 kg/m2 booster grade 0.56~0.70 kg/m2

Surface treatment: sandblasting or shot blasting rust removal up to Sa2.5 grade, anchor grain depth 50~80um.

Workpiece preheating: Generally adopt medium frequency heating, workpiece temperature control in the range of 220℃~240℃, shall not exceed 260℃.

Spraying construction: adjust the spray gun and workpiece to make the film reach the specified thickness.

Quenching time: at 230℃, the time from spraying to quenching shall not be less than 90 s

Coating cooling: cooling to below 95℃, surface inspection.

Repair leaks: After detection of leaks, rough treatment, and then use our company's liquid epoxy heavy corrosion coating SLH07 for repair.

This powder coating product is coated on preheated workpiece, using waste heat curing, generally do not need later baking. However, when the workpiece wall is too thin or the outside temperature is too low, additional heating curing should be considered.

Cangzhou Shenlong pipeline production can implement the following standards:

SY/T0315-2013 Technical Standard for Weld bonded epoxy Powder Outer Coating on Steel Pipe

CAN/CSA-Z245.20 "FBE Coating for Steel Tube Outer Wall"

DIN30671 technical standard for fused epoxy powder outer coating on steel tubes and fittings

Cangzhou shenlong pipe manufacturing co., ltd. Is engaged in oil, gas, water, coal slurry mixing medium steel pipeline coating operations, anti-corrosion, insulation, piping is set in a body's specialized pipeline engineering precast construction enterprises, products used in oil pipeline, chemical piping, electrical, pipe, gas pipe, heat pipes, sewage pipes, etc. Anti-corrosion processing of straight pipe and bend pipe DN40-3000 three-layer structure polyolefin (PE, PP, TPEP,3LPE) steel pipe coated with anti-corrosion, DN40-3800 steel hot stewed bend pipe and pipe fittings coated with FBE, epoxy resin coating anti-corrosion, DN40-3800 steel pipe inner wall resistance reduction, solvent-free epoxy steel pipe, epoxy paint anti-corrosion, Coated plastic steel pipe, dip plastic steel pipe. Lined with plastic steel pipe PE,PO,PP,PTFE,HDPE, polymer polyethylene corrosion. The company is in strict accordance with China Petroleum and Natural Gas SY/T0413-2002, national GB/T23257-2009, German DIN 30670, American AWWA C210 and other international and domestic anti-corrosion standards.