Product List

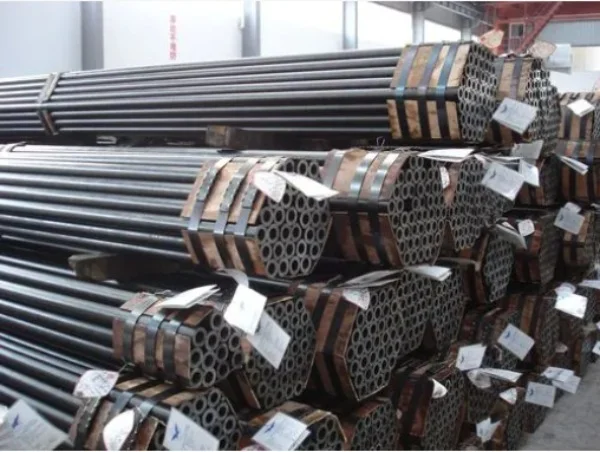

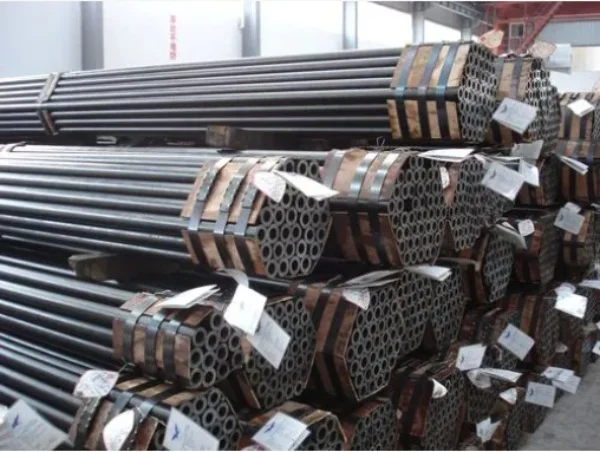

EN 10216 Seamless Pipe

Standard:EN 10216-1

EN 10216-1 Standard specifies the technical delivery conditions for two qualities TR1 and TR2 of seamless tubes of circular cross section with specified room temperature properties made of non-alloy quality steel.

Specifictions of EN 10216-1 P235 Seamless steel tubes for pressure purposes

Outside diameter: 21.3mm-914mm

Wall Thickness: 2mm-50mm

Length: Fixed(6m,9m,12,14m) or normal length(5-12m)

Ends: Plain End, Beveled End, Threaded

Manufacturing process of EN10216 Seamless pipe

Steels shall be fully killed.

NOTE : This excludes the use of rimming, balanced or semi-killed steel.

The steel name:

(1)the capital letter P for pressure purposes;

(2)the alphanumeric TR1 for qualities without specified aluminium content, impact properties and specific inspection and testing requirements ;

(3)the alphanumeric TR2 for qualities with specified aluminium content, impact properties and specific inspection and testing requirements.

Tube manufacture and delivery conditions

EN 10216-1 P235 Seamless steel tubes will be manufactured by a seamless process. The forming operations and delivery conditions are shown in Table 1.

Table 1 — Forming operations and delivery conditions

Forming operation | Quality | Delivery condition |

Hot formed | TR1 | As formed or normalized or normalizing-formed |

TR2 | Normalized or normalizing-formed | |

Hot formed + cold finished | TR1 and TR2 | Normalized |

Chemical composition of EN 10216-1 P235

Chemical composition (cast analysis) a in % by mass for quality TR2

Steel grade | Steel | C | Si | Mn | P | S | Cr | Mo |

P235TR2 | 1.0255 | 0,16 | 0,35 | 1,20 | 0,025 | 0,015 | 0,30 | 0,08 |

Ni max. | Al tot min. | Cu max | Nb max. | Ti max. | V max. | Cr+Cu+Mo+Ni max. |

0,30 | 0,02 | 0,30 | 0,010 | 0,04 | 0,02 | 0,70 |

Chemical composition (cast analysis) a in % by mass for quality TR1

Steel grade | Steel | C | Si | Mn | P | S | Cr | Mo |

P235TR1 | 1.0254 | 0,16 | 0,35 | 1,20 | 0,025 | 0,020 | 0,30 | 0,08 |

Ni max. | Al tot min. | Cu max | Nb max. | Ti max. | V max. | Cr+Cu+Mo+Ni max. |

0,30 | - | 0,30 | 0,010 | 0,04 | 0,02 | 0,70 |

Mechanical properties of EN 10216-1 P235

Mechanical properties for quality TR2

Steel grade | Tensile properties | Impact properties | ||||||||

Steel name | Steel | Upper yield strength | Tensile | Elongation | Minimum average | |||||

T ≤ 16 | 16 < T ≤ 40 | 40 < T ≤ | l | t | ||||||

MPa * | MPa * | MPa * | MPa * | l | t | 0 | -10 | 0 | ||

P235TR2 | 1.0255 | 235 | 225 | 215 | 320 to 440 | 25 | 23 | 40 | 28 d | 27 |

Note: l = longitudinal t = transverse

Mechanical properties for quality TR1

Steel grade | Tensile properties | Impact properties | ||||||||

Steel name | Steel | Upper yield strength | Tensile | Elongation | Minimum average | |||||

T ≤ 16 | 16 < T ≤ 40 | 40 < T ≤ | l | t | ||||||

MPa * | MPa * | MPa * | MPa * | l | t | 0 | -10 | 0 | ||

P235TR1 | 1.0254 | 235 | 225 | 215 | 360 to 550 | 25 | 23 | - | - | - |

Note: l = longitudinal t = transverse

Tolerances of EN 10216-1 Seamless steel tubes

Tolerances on outside diameter and on wall thickness

Outside | Tolerances on D | Tolerances on T for a T/D ratio | |||

≤ 0,025 | > 0,025 | > 0,050 | > 0,10 | ||

D ≤ 219,1 | ± 1% or ± 0,5 mm whichever is the greater | ± 12,5 % or ± 0,4 mm | |||

D > 219,1 | ± 20 % | ± 15 % | ± 12,5 % | ± 10 % a | |

a For outside diameters D ≥ 355,6 mm it is permitted to exceed the upper wall thickness locally by a further 5 % of the wall thickness T | |||||

Tolerances on exact lengths

Length L | Tolerance on exact length |

L ≤ 6 000 | + 10 |

6 000 < L ≤ 12 000 | +15 |

L > 12 000 | +by agreement 0 |