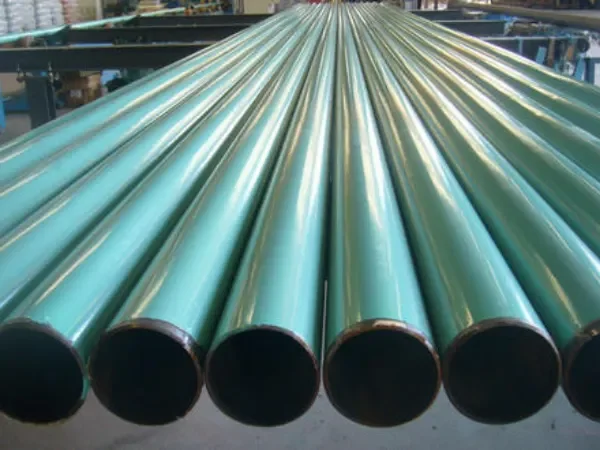

Epoxy powder anti-corrosive steel pipe

Epoxy powder anticorrosive steel pipe

Epoxy powder anti-corrosion can be used on the outside of the pipeline and can also be used in the inner wall of the pipeline, in order to prevent corrosion in the pipeline, reduce friction resistance, improve the transmission, and coat on the inner wall of the pipe film. Commonly used coatings are amine-cured epoxy and polyamide epoxy with coating thicknesses ranging from 0.038 to 0.2 mm. In order to ensure that the coating is firmly bonded to the pipe wall, the inner wall of the pipe must be treated. Since the 70s tend to tube, outer wall coating selection of the same material, so that tube, outer wall coating at the same time.

Epoxy powder anti-corrosion steel pipe anti-corrosion insulation coating: In the medium and small caliber heat transport of crude oil or fuel oil pipeline, in order to reduce the pipeline to the soil heat dissipation, in the pipeline external with insulation and anti-corrosion composite layer. The commonly used insulation material is hard polyurethane foam, suitable for the temperature of -185 ~ 95℃. To strengthen the soft material, a layer of high-density polyethylene is placed on top of the insulation, forming a composite structure to prevent groundwater from seeping into the insulation.

Cangzhou shenlong pipe manufacturing co., ltd. Is engaged in oil, gas, water, coal slurry mixing medium steel pipeline coating operations, anti-corrosion, insulation, piping is set in a body's specialized pipeline engineering precast construction enterprises, products used in an oil pipeline, chemical piping, electrical, pipe, gas pipe, heat pipes, sewage pipes, etc. Anti-corrosion processing of straight pipe and bend pipe DN40-3000 three-layer structure polyolefin (PE, PP, TPEP,3LPE) steel pipe coated with anti-corrosion, DN40-3800 steel hot stewed bend pipe and pipe fittings coated with FBE, epoxy resin coating anti-corrosion, DN40-3800 steel pipe inner wall resistance reduction, solvent-free epoxy steel pipe, epoxy paint anti-corrosion, Coated plastic steel pipe, dip plastic steel pipe. They are lined with plastic steel pipe PE, PO, PP, PTFE, HDPE, and polymer polyethylene corrosion. The company is in strict accordance with China Petroleum and Natural Gas SY/T0413-2002, national GB/T23257-2009, German DIN 30670, American AWWA C210, and other international and domestic anti-corrosion standards.