Factors affecting corrosion resistance and service life of coatings

Factors affecting corrosion resistance and life of coatings

1. Composition and structure of coating itself

The requirements for coating are generally in three aspects: good process performance, coating operation is simple and easy to master, easy to adjust diverse types; Low economic cost means low "cost/function"; Environmentally friendly means to save resources, reduce pollution, use reusable or renewable products

The technological performance of the coating is closely related to the composition and structure of the coating itself. The composition and structure of the coating itself are reflected in the viscosity, fluidity, curing time, adhesion, and other properties of the coating. Because of the different service environments of pipeline construction, the requirements of pipeline coating are also different. According to different pipe service requirements, the coating also has specific requirements. If the pipeline corrosion resistance and thermal conductivity are required to be good, the coating in addition to the basic performance also requires good corrosion resistance, and good thermal conductivity; The pipeline service environment must be antistatic. The coating must have good antistatic performance in addition to the basic performance. Therefore, when choosing the coating, we must choose the coating that is consistent with the actual service environment of the pipeline. After choosing the coating that is consistent, we are required to choose the green environmental protection coating with high quality, low cost, and no pollution.

2. Pretreatment of coating and metal matrix

The pretreatment of coating and metal matrix is mainly divided into two aspects: sandblasting and spray painting, and sandblasting is more critical. Sandblasting can not only remove the rust layer, old paint layer, and other dirt on the surface of the steel pipe but also make the surface of the steel pipe form uniform small pitting spots, which can improve the adhesion between the coating and metal, improve the anti-corrosion effect and service life of the coating. In the process of sandblasting, quartz sand with different particle sizes or quartz sand mixed with steel balls in accordance with a certain proportion will be selected for sandblasting, which will have a better effect. According to the requirements of the construction pipeline, the requirements of sandblasting for rust removal are different, and the effect of sandblasting for rust removal is determined according to the "Corrosion Grade and Rust Removal Grade of Steel Surface before coating". Before painting, the pipe should be cleaned, so that the adhesion strength between the coating and the metal matrix can be increased. According to different requirements, the thickness of the spray paint and the uniformity of the film surface also change.

3. Adhesion strength between coating and substrate

At present, the binding force between the coating and metal matrix is mainly characterized by coating capacitance. Grundmeier et al. [believe that maintaining interface adhesion is the main factor affecting coating protection. The determination of adhesion of coating based on electrochemical impedance spectroscopy (EIS) has certain limitations, but it can be determined that there is a corresponding (proportional) relationship between coating capacitance and service adhesion of coating, the smaller the coating capacitance, the stronger the adhesion and the smaller the peel.

4. Permeability resistance of the coating to water and ions and its service environment

The permeability resistance of the coating to water and ions is also one of the factors affecting the quality of the coating. Changes in the water absorption process of the organic coating soaked in the medium occur before the loss of adhesion at the coating/metal interface, the electrochemical reaction, and the decrease of the coating's resistance to ion transport [8]. The beginning of coating failure is the poor permeability resistance of the coating to water and ions, which will induce the penetration of oxygen and other corrosive substances, resulting in the high speed of these corrosive substances reaching the coating/metal interface, leading to the corrosion under the coating. So the more impermeable the coating is to water and ions, the longer the coating will last, and the longer the service pipe will last.

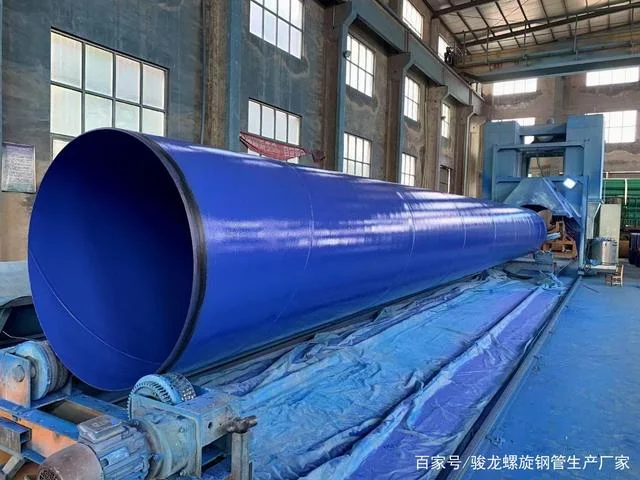

Cangzhou shenlong pipe manufacturing co., ltd. Is engaged in oil, gas, water, coal slurry mixing medium steel pipeline coating operations, anti-corrosion, insulation, piping is set in a body's specialized pipeline engineering precast construction enterprises, products used in an oil pipeline, chemical piping, electrical, pipe, gas pipe, heat pipes, sewage pipes, etc. Anti-corrosion processing of straight pipe and bend pipe DN40-3000 three-layer structure polyolefin (PE, PP, TPEP,3LPE) steel pipe coated with anti-corrosion, DN40-3800 steel hot stewed bend pipe and pipe fittings coated with FBE, epoxy resin coating anti-corrosion, DN40-3800 steel pipe inner wall resistance reduction, solvent-free epoxy steel pipe, epoxy paint anti-corrosion, Coated plastic steel pipe, dip plastic steel pipe. They are lined with plastic steel pipe PE, PO, PP, PTFE, HDPE, and polymer polyethylene corrosion. The company is in strict accordance with China Petroleum and Natural Gas SY/T0413-2002, national GB/T23257-2009, German DIN 30670, American AWWA C210, and other international and domestic anti-corrosion standards.