Product List

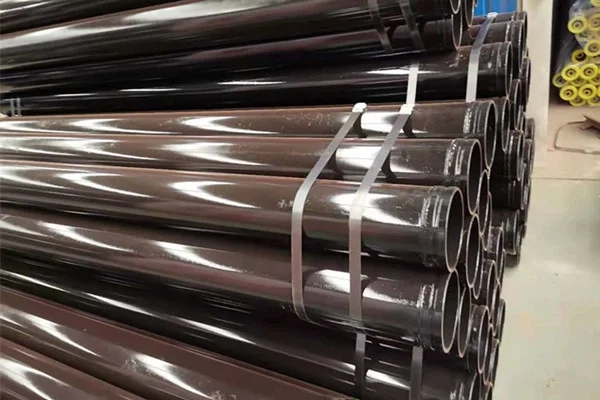

Fire fighting steel pipe

Product name: Fire fighting steel pipe, Steel pipe for fire fighting system, fire sprinkler pipe material, fire sprinkler materials, fire line pipe

Materials: GR.B, X42, ST35, S195T, ST52, S235JR, S355JR, SS400, SGP, STP G370 etc.

Standard: API 5L, ASTM A53, A106, ASTM A789, ASTM A795 etc.

Fire fighting steel pipe type

Fire fighting welded pipe, Fire fighting seamless pipe, Fire fighting galvanized pipe, Fire fighting red painted steel pipe, Threaded steel pipe,Grooved tube

Fire fighting specification:

Outer diameter:1/2”-26”(21.3mm-660.4mm).

Wall thickness: 2mm-25.4mm.

Length: 2m-12m.

Surface treatment: high temperature resistant epoxy powder;High temperature resistant red paint;general black paint; hot dip galvanized

Fire fighting steel pipe feature

High-frequency straight seam electric-resistance welded steel pipe(erw steel pipe) is hot-rolled coil after forming machine, the use of high-frequency current skin effect and proximity effects, the tube edge heating and melting, squeeze roller under pressure welding to achieve production.

Fire fighting steel pipe process

High-frequency straight seam electric-resistance welded (ERW), Seamless steel pipe(Hot rolled; Cold drawn)

Fire fighting steel pipe origin

China

Fire fighting steel pipe application

Widely used in gas & oil conveying, mine and oilfield drilling.

Fire fighting steel pipe annual

10,000 tons

Fire fighting steel pipe advantage

Competitive Price

Standard Complied Quality

Strict Quality Control

Considerate after-sale service

Fast delivery

Available EN10204 3.1 Certificate can be provided

Mill ISO certificate

Mill Product Catalog

Available Detailed Mill Company Profile

Available Mill Quality Manual

Available Mill ITP

Available Mill Past Project list

Fire fighting steel pipe inspection

Hydrostatic testing, ultrasonic testing, eddy current testing, magnetic particle testing, impact testing, hardness testing, etc.

Fire fighting steel pipe package and storage

Safe and Seaworthy packing suitable for export; As per customer’s requirement.

Fire fighting steel pipe warranty

36 months

Fire fighting steel pipe quality inspection:

1. Our factory has its own "experimental testing center".CNAS Laboratory Accreditation Certificate

2.Control quality strictly.The first pass is the quality inspection on the production line,The second pass is full inspection of the production quality .

3.We have got internationally recognized certificates, ISO, CE, LR,Philippine certificate,also support third-party testing,as SGS, BV, ect.

Fire fighting steel pipe installation process

Installation preparation → main pipe installation → alarm valve installation → riser installation → spray layered main pipe, fire hydrant and branch pipe installation → water flow indicator, fire pump, high-level water tank, water pump combiner installation → pipeline pressure test → pipeline flushing → sprinkler head Branch pipe installation (system comprehensive pressure test and flushing) → throttling device installation → alarm valve accessories, fire hydrant accessories, sprinkler head installation → system water test

Fire fighting steel pipe market prospect

At present, with the requirements of development, various new fire-fighting pipes and connection technologies continue to emerge, and they have been effectively applied in various practical projects. These need to be summarized, so that various fire-fighting pipes are more suitable for various fire-fighting system applications. Accurate and economical.