How to Distinguish the Quality of Epoxy Coated Steel Pipes?

Epoxy coated steel pipe is a common pipeline material, which has the advantages of being anti-corrosion, wear-resistant and corrosion-resistant, and is widely used in petroleum, chemical, natural gas, and other fields. However, there are coated steel pipes of varying quality on the market, and how to distinguish their quality has become the focus of consumers' attention. The following describes how to distinguish its quality from several aspects.

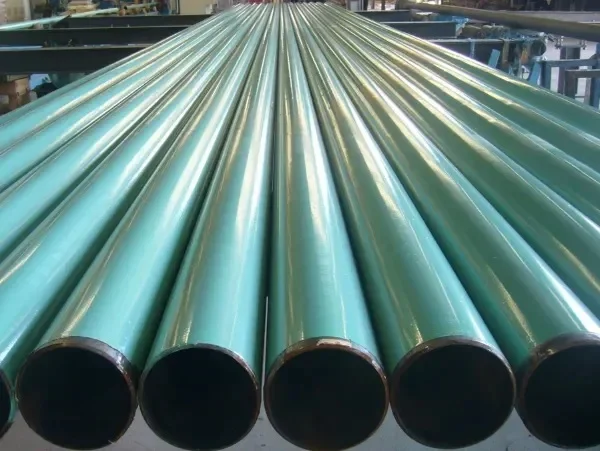

1. Appearance quality

The appearance quality of epoxy coated steel pipe is one of the important indicators to judge its quality. The high-quality coated steel pipe has a smooth surface, no bubbles, no cracks, no pitting, no scratches, and other defects, with uniform coating and high gloss. However, the surface of poor-quality coated steel pipes is not smooth, and there are defects such as bubbles, cracks, pits, scratches, etc., the coating is uneven and the gloss is low.

2. Coating thickness

The coating thickness of epoxy coated steel pipe is also one of the important indicators to judge its quality. If the coating thickness is too thin, the steel pipe will be susceptible to corrosion, while if the coating thickness is too thick, the strength and pressure resistance of the steel pipe will be affected. Generally speaking, the coating thickness should be above 0.2mm, but not more than 0.5mm.

3. Steel pipe material

The material of epoxy coated steel pipe is also one of the important indicators to judge its quality. The high-quality oxygen-coated steel pipe is made of high-quality steel, which has the characteristics of high strength, corrosion resistance, and wear resistance. Inferior coated steel pipes are made of inferior steel, which has low strength, is easy to corrode, and is easy to wear.

4. Corrosion resistance

Epoxy coated steel pipes are mainly used to transport corrosive media, and their corrosion resistance is one of the important indicators for judging their quality. High-quality coated steel pipe has good corrosion resistance and can be used in harsh environments for a long time without corrosion. However, inferior-coated steel pipes have poor corrosion resistance and are prone to corrosion, resulting in pipeline leakage.

5. Production process

The production process of epoxy coated steel pipe is also one of the important indicators to judge its quality. High-quality coated steel pipe adopts advanced production technology, such as spraying, drying, curing, and other links are strictly controlled to ensure stable coating quality. However, the production process of inferior coated steel pipes is simple and rough, and the coating quality is unstable.

To sum up, to distinguish the quality of coated steel pipes, it is necessary to comprehensively consider the appearance quality, coating thickness, steel pipe material, production process and other aspects. When consumers purchase epoxy coated steel pipes, they should choose products produced by regular manufacturers and avoid buying inferior products.

What does epoxy-coated steel pipe storage pay attention to?

What do you need to pay attention to when installing epoxy coated steel pipe?

Characteristics and advantages of epoxy coating