How to avoid corrosion in anti-corrosion steel pipe

How to avoid corrosion in anti-corrosion steel pipe?

First, the corrosion prevention layer of anticorrosive steel pipe:

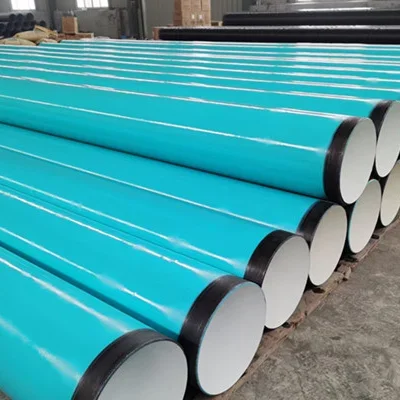

Anticorrosive steel pipe is a buried metal body. In order to prolong the service life, steel conduit and lead-sealed aluminum cable are usually equipped with an anticorrosive layer on the outside. As the anticorrosion layer material of steel pipe, various types of insulation materials are used, such as asphalt, coal tar coating, epoxy asphalt, or polyethylene. However, after a period of use, various environmental factors inevitably lead to the appearance of an aging phenomenon. In the actual pipeline engineering and service environment, despite careful construction, the corrosion layer cannot be guaranteed to be defect free. If there is a defect in the corrosion-resistant steel pipe, it will cause a perforation faster than the bare steel pipe.

Two, anti-corrosion steel pipe advantages:

1. The steps of anticorrosive steel pipe are simple and convenient. It can be constructed directly in the factory or on-site.

2. The anti-corrosion pipeline has a longer life because the pipeline itself has anti-corrosion performance, coupled with the additional anti-corrosion setting of the steel pipe, which greatly improves the overall service life of the pipeline. The general service life of up to 30 years, can save maintenance and other costs.

3. Low economic cost and service life can form a reasonable proportion of the investment.

4 Anticorrosive steel pipe environmental protection design, in line with the needs of The Times. Because in the future, the environmental protection requirements for steel pipe conveying fluid become more strict, the products that cannot meet the environmental protection requirements will be gradually eliminated.

It can be seen from the above four points that anti-corrosion steel pipe will play an important role in the development of pipelines. In the future, the construction of pipeline projects will mainly use anticorrosive steel pipes.

Three, how to avoid corrosion phenomenon in anti-corrosion steel pipes?

1. Metal anti-corrosion protection method

The protective layer of various materials is manufactured on the metal surface to separate the metal products from the external corrosive medium, which can be formed by applying, hot plating, spraying, electroplating, etc.

2. Change the method of metal anti-corrosion structure

Change the structure of metals. Because some heavy metals have low chemical activity and are not easy to be corroded by other substances, the combination of some metals with other metals can effectively improve corrosion resistance.

3. Treatment method of metal anti-corrosion medium

Metal corrosion resistance can be achieved by treating the corrosive medium, and adding corrosion inhibitors to the corrosive medium.

Cangzhou shenlong pipe manufacturing co., ltd. Is engaged in oil, gas, water, coal slurry mixing medium steel pipeline coating operations, anti-corrosion, insulation, piping is set in a body's specialized pipeline engineering precast construction enterprises, products used in an oil pipeline, chemical piping, electrical, pipe, gas pipe, heat pipes, sewage pipes, etc. Anti-corrosion processing of straight pipe and bend pipe DN40-3000 three-layer structure polyolefin (PE, PP, TPEP,3LPE) steel pipe coated with anti-corrosion, DN40-3800 steel hot stewed bend pipe and pipe fittings coated with FBE, epoxy resin coating anti-corrosion, DN40-3800 steel pipe inner wall resistance reduction, solvent-free epoxy steel pipe, epoxy paint anti-corrosion, Coated plastic steel pipe, dip plastic steel pipe. They are lined with plastic steel pipe PE, PO, PP, PTFE, HDPE, and polymer polyethylene corrosion. The company is in strict accordance with China Petroleum and Natural Gas SY/T0413-2002, national GB/T23257-2009, German DIN 30670, American AWWA C210, and other international and domestic anti-corrosion standards.