Product List

Piping System and Spools

Pipe Spools

A pipe spool is an assimilation of piping components, which is prefabricated in a piping shop, for installation in the field. They are often flanged to facilitate the connection to other spools.

Pipe spools are the pre-build parts of a piping system. Pipes, flanges, and fittings are called pipe spools and they are produced before they are used in the piping system.

Why pipe spools are pre-fabricated?

Cost Savings in Fabrication, Inspection & Testing

Cost Savings in Fabrication, Inspection & Testing Quality of the work is easier to manage & maintain in a controlled environment. High accuracies on specified tolerances will avoid rework at site.

Quality of the work is easier to manage & maintain in a controlled environment. High accuracies on specified tolerances will avoid rework at site. Weather independent fabrication will minimize production delays.

Weather independent fabrication will minimize production delays. Prefabricated Spools are the perfect answer to severe skill & labor shortage. Users do not have to mobilize significant work force for fabrication of spools on site.

Prefabricated Spools are the perfect answer to severe skill & labor shortage. Users do not have to mobilize significant work force for fabrication of spools on site. Economies of Scale will result in lesser costs of fabrication in mass production vis – a – vis

Economies of Scale will result in lesser costs of fabrication in mass production vis – a – vis Prefabricated Spools will take lesser fabrication / assembly time, thereby avoiding time & cost overruns.

Prefabricated Spools will take lesser fabrication / assembly time, thereby avoiding time & cost overruns. Prefabricated Spools will entail no or little investments in fabrication & testing equipments.

Prefabricated Spools will entail no or little investments in fabrication & testing equipments.

Prefabricated spools workshop

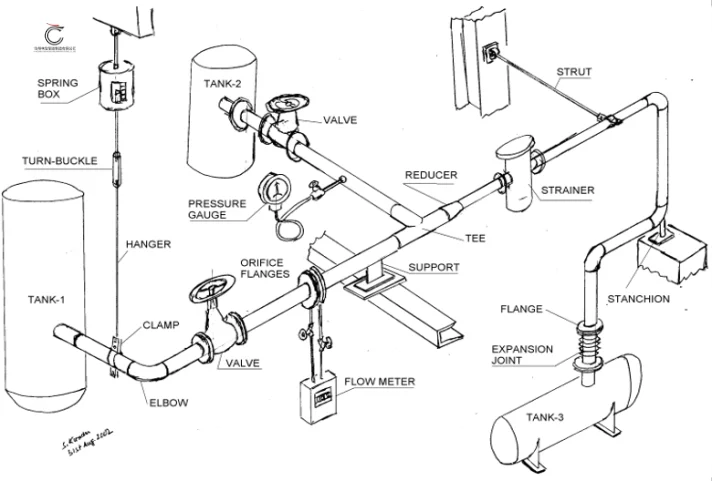

Piping system is a network of pipes, fittings and valves intended to perform a specific job i.e. to carry or transfer fluids from one equipment to another.

A schematic diagram of a piping system is shown on the right:

Components of Piping System

The most common components of a piping system are pipes, fittings and valves.

Pipes: Pipes are long cylinders used to carry or transfer fluids. The most common fluids are water, oil, steam, air, milk or finished products like paints, juices. Other uncommon examples include pulp, acids, alkalies, chemicals etc.

Pipe Fittings: Pipe fittings are used to connect lengths of pipes to construct a long piping system; commonly used fittings are flanges, elbows, tees, reducers, expansion bellows etc.

Valves: Valves are used to stop, divert or control fluid flow. Common valve types are gate valves, globe valves, butterfly valves, ball valves, control valves; the selection is based on intended function and application.

In addition, a number of devices like strainers, traps, expansion loops are necessary for keeping the fluid clean and in good condition, and to accommodate expansion/contraction due to temperature variations.

Material for Piping Systems

Piping system may consist of a variety of materials including mild steel, stainless steel, aluminum, brass, copper, glass or plastic. Usually, pipe fittings and valves are made of the same material as the pipe. The material selection as well as pipe sizing depends upon parameters like nature of fluid, pressure, temperature and flow rate.

Carbon steel:

ASTM A53- welded and seamless pipe, black and galvanised.

ASTM A106- Seamless cs pipe for high temperature services.

ASTM A672- Electric fusion welded steel pipe for high pressure service at moderate temperature services.

Stainless steel:

ASTM A312- Seamless and welded steel pipe for low temperature services.

A409-welded large diameter austenitic steel pipe for corrosive and high temperature services.

ASTM A358- Electric fusion welded austenitic chrome -nickel steel pipe for high temperature services.

Low alloy steel:

ASTM A335- Seamless ferritic alloy steel pipe for high temperature services.

ASTM A691- Carbon and alloy steel pipe, electric fusion welded for high pressure service at high temperature.

Low temperature carbon steel:

ASTM A333- Seamless and welded steel pipe for low temperature services.

ASTM A671- Electric fusion welded steel pipe for atmpospheric and low temperature services(sizes >=16in NB)

The plumbing network supplying water at your home is a common example of a piping system. Other more rigorous examples include steam piping in a power plant, milk piping in a dairy, paint piping in a paint manufacturing plant, oil piping in a refinery, so and so forth.

Application of piping system

The plumbing network supplying water at your home is a common example of a piping system. Other more rigorous examples include steam piping in a power plant, milk piping in a dairy, paint piping in a paint manufacturing plant, oil piping in a refinery, so and so forth.