Product List

Precision seamless steel pipes

Product name: Seamless Precision Steel Pipe, Precision tube, seamless precision tube, fine rolled bright tube, thick wall fine rolled bright tube, thin wall fine rolled bright tube, precision shaped tube, seamless bright tube

Materials: GR.B, X42, X52,ST37, ST44, ST52, E235N, E355N, TP304,TP316L etc.

Standard: EN10305, A106, A53, A519, DIN2391, DIN2448, GOST8731, JIS G3454.

Precision seamless steel pipes description

Seamless precision steel pipe is a high-precision steel tube formed by cold drawing or cold rolling. It has high dimensional accuracy, good concentricity, and smooth surface finish. It is mainly used for manufacturing parts with high precision requirements and long service life.

Precision seamless steel pipes specification:

Outer diameter: 10-273mm

Wall thickness: 1.5mm-15mm

Length: 0.5m-12m

Dimensional accuracy:

1. Tolerance of inside and outside diameter ≤±0.025mm;

2. Tolerance of wall thickness ≤±0.05mm;

3. Concentricity tolerance ≤0.05mm;

4. Straightness less than 0.30mm/m.

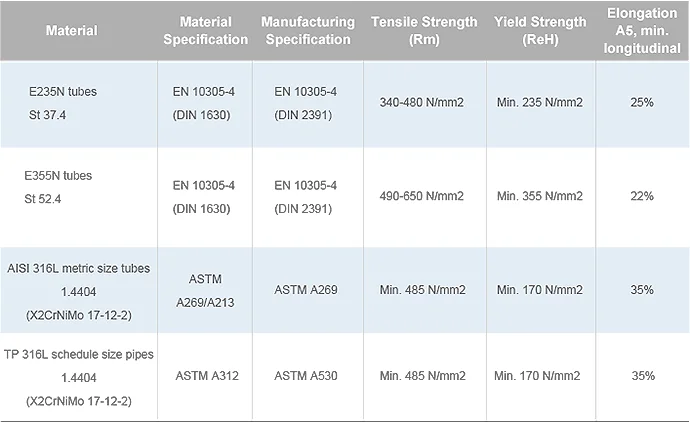

Mechanical property of precision seamless steel pipes

Precision seamless steel pipes use:

Seamless precision steel pipe is mainly used in the manufacture of parts such as automobiles, motorcycles, home appliances, and medical equipment. It is also suitable for the manufacture of high-precision hydraulic pipes, and for high-pressure oil pipes and gas pipelines.

1. Auto parts, auto parts; Car shock absorbers and so on.

2. Motor shell, motor shell, DC motor cylinder; Etc.

3. Industrial processing: mechanical processing, bearing sleeve, processing machinery parts, etc.;

4. Hydraulic cylinder, cylinder, etc.;

5. Others: electrical gas transmission, water power generation fluid pipeline

Precision seamless steel pipes feature:

1. The finished pipe has high dimensional accuracy, the inner and outer diameter can be accurate within 0.03mm;

2. Good internal and external surface finish;

3. After cold rolling, there is no oxide skin, scratch, scratch or defect on the inside and outside surface of the steel pipe;

4. Steel pipe expansion, shrinkage, flattening, bending without cracks, cold bending without deformation, can withstand middle and high pressure;

5. Superior performance, can make a variety of complex deformation and mechanical deep processing

Precision seamless steel pipes advantages

Precision seamless steel pipes offer a number of advantages over traditional steel pipe products. These include superior strength, corrosion resistance, and excellent wear resistance. They are also resistant to stress corrosion cracking and can be welded to other materials.

1. Cold-rolled precision steel pipe has high tolerance dimension accuracy, the product accuracy is controlled within ±0.05mm, the inside and outside wall finish is good, and the surface has no oxide layer.

2. The comprehensive performance of cold-rolled precision steel pipe is excellent, can withstand high pressure, cold bending, flaring, flattening no cracking, no wrinkled skin, and can do a variety of complex deformation and mechanical processing.

3. The popularization and application of precision seamless tubes can save steel, improve processing efficiency, reduce processing procedures and equipment investment, save costs and greatly save machining hours, improve production and material utilization, and help improve product quality and reduce costs.

Precision steel pipe is a kind of high-precision steel pipe material after cold drawing or hot rolling. Due to the advantages of no oxide layer on the inner and outer walls of precision steel pipe, no leakage under high pressure, high precision, high finish, cold bending no deformation, flaring, flattening without cracks, etc., it is mainly used for the production of pneumatic or hydraulic components, such as cylinder or cylinder, can be a seamless pipe, but also welded pipe.

The difference between ordinary seamless steel pipe and precision steel pipe

1, seamless steel pipe is mainly characterized by no welding joints and can withstand greater pressure. The product can be very rough cast or cold-drawn.

2, precision steel pipe is a modern product, mainly the inner hole, and outer wall size have strict tolerance and roughness.