Seamless Square Tube: A Durable Solution for Structural Needs

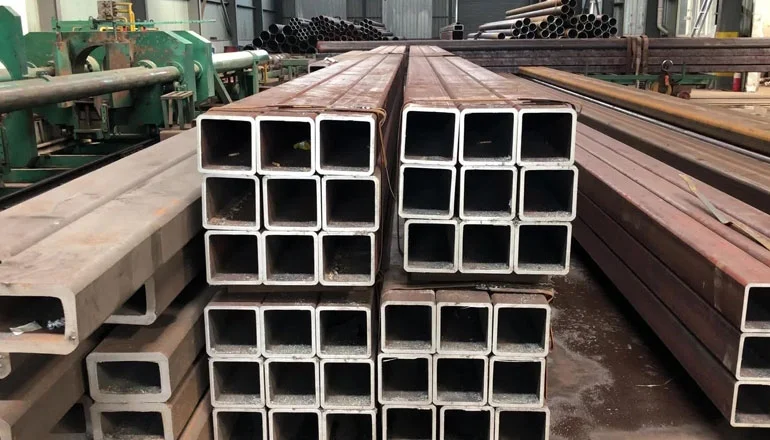

A seamless square tube represents a type of hollow structural section (HSS) extensively utilized across diverse applications, with a pronounced presence in the construction sector. It stands out by its square or rectangular profile, featuring impeccably even walls devoid of any discernible weld seams. This seamlessness is a product of a specialized manufacturing procedure that entails piercing a solid cylindrical billet to form a hollow tube, obviating the necessity for welding.

The eminence of seamless square tubes within the construction industry cannot be overstated. They are prized for their exceptional strength, resilience, aesthetic appeal, and versatility. The seamlessness of their construction renders them well-suited to meet the exacting demands of contemporary construction projects, rendering them a favored choice for a multitude of applications within the sector.

Key Features and Advantages of the Seamless Square Tube

Seamless square tube comes equipped with a range of essential features and advantages that render them exceptionally beneficial across diverse applications, with a particular focus on the construction industry

Durability

Seamless square tubes showcase outstanding resistance to corrosion, ensuring an extended lifespan compared to their seamed counterparts. This heightened durability is pivotal for structures exposed to harsh environmental conditions.

Strength

These tubes exhibit impressive load-bearing capacity, even in the absence of joints and welds. Their inherent strength makes them well-suited for supporting substantial loads, contributing to structural robustness.

Design Flexibility

Seamless square tubes can be crafted in various sizes and dimensions, granting designers and engineers the flexibility to tailor them to specific project requirements. This adaptability fosters the development of innovative and tailored design solutions.

Aesthetic Appeal

The seamless construction eliminates visible seams or welds, resulting in a cleaner and more aesthetically pleasing appearance. This visual finesse proves particularly advantageous in architectural and decorative applications where aesthetics are paramount.

Reduced Risk of Defects

The seamless fabrication of these tubes substantially diminishes the likelihood of structural weaknesses or defects that may arise from welds or seams. This characteristic bolsters the reliability and safety of structures employing these tubes.

Seamless square tubes offer a compelling blend of durability, strength, design flexibility, aesthetic refinement, and reduced structural vulnerabilities. These attributes establish them as a prized choice within the construction industry and other realms where the demand for resilient and visually appealing solutions is paramount.

Applications of the Seamless Square Tube

The seamless square tube is incredibly versatile and find widespread use across various industries, owing to their unique attributes. Here are prominent areas where seamless square tubes are routinely employed:

Structural Frameworks

Seamless square tubes assume a fundamental role in erecting the essential frameworks of buildings, bridges, and towering structures. Their exceptional strength and resilience are instrumental in ensuring structural stability and integrity in these expansive projects.

Industrial Machinery

Within industrial settings, these tubes are the go-to choice for fabricating equipment frames and providing essential structural support. They are indispensable for upholding the sturdiness and rigidity of heavy-duty machinery and equipment.

Automotive Industry

In the automotive sector, seamless square tubes are harnessed for crafting chassis, frames, and roll cages. Their robustness and durability substantially enhance vehicle safety and overall performance.

Furniture and Home Appliances

Within the realm of furniture manufacturing, seamless square tubes are favored for shaping various components such as table legs, chair frames, and other structural elements. They contribute not only to stability but also offer a sleek and contemporary aesthetic.

Energy Sector

Seamless square tubes are of paramount importance in the energy sector, notably for applications involving oil and gas pipelines and drilling rigs. Their capacity to endure harsh environmental conditions, coupled with resistance to corrosion, makes them the ideal choice for these demanding environments.

These applications underscore the remarkable versatility of seamless square tubes, where their blend of strength, durability, and visual appeal establishes them as an essential component in a diverse array of industries and projects.

Environmental and Economic Advantages

Seamless square tubes offer a range of environmental and economic advantages that make them a responsible and cost-effective choice in various applications:

Efficient Material Usage

The manufacturing process for seamless square tubes is highly efficient, resulting in less material wastage compared to seamed tubes. This efficiency minimizes resource consumption during production.

Sustainability

Seamless square tubes have a long lifespan due to their durability and resistance to corrosion. This extended service life reduces the need for frequent replacements, contributing to sustainability by decreasing the demand for new materials and reducing waste.

Economic Benefits

Businesses and homeowners benefit economically from the use of seamless square tubes. Their inherent durability means lower long-term costs, as they require fewer replacements and maintenance interventions over time.

Reduction in Maintenance Costs

The absence of seams in seamless square tubes reduces potential points of failure. This results in fewer maintenance and repair requirements, further enhancing the economic advantages and reducing the overall lifetime cost of structures and equipment.

CONCLUSION

In conclusion, seamless square tube represents a remarkable innovation with a broad spectrum of applications and benefits, particularly in the construction industry. These tubes, characterized by their durability, strength, design flexibility, clean appearance, and reduced risk of defects, have become integral components in various industries.

With their ability to enhance structural integrity, support heavy loads, and provide aesthetic appeal, seamless square tubes have earned their place as an indispensable choice in the construction of buildings, bridges, industrial machinery, automotive components, furniture, and energy sector applications.

As technology continues to advance and industries demand stronger, more reliable, and aesthetically pleasing solutions, seamless square tubes are poised to remain a critical and enduring element in modern construction and manufacturing, offering a blend of strength, sustainability, and economic efficiency.