Product List

Sockolet

Product name: Sockolet, Threadolet, Weldolet, pipe outlet, threadolet welding, Branch Connection Fittin gs

Specifications:1/2NPS-4”NPS

Wall thickness: SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc.

Pressure: 2000#,3000#,6000#,9000#

Sockolet, Threadolet, Weldolet material:

Carbon steel flange (CS) : ASTM A105, LF1, LF2 CL1/CL2, LF3 CL1/CL2, ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65, F70;

Stainless steel flange (SS) : ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8;

Alloy flange (AS) : ASTM A182F1, F5a, F9, F11, F12, F22, F91, A182F12, A182F11, 16MnR, Cr5Mo, 12Cr1MoV, 15CrMo, 12Cr2Mo1, A335P22, ST45.8;

Sockolet,Threadolet,Weldolet Standards:ANSI B16.11, EN10241, MSS SP 97 ,MSS SP 83, MSS SP 95 etc.

Branch Connection Fittings :

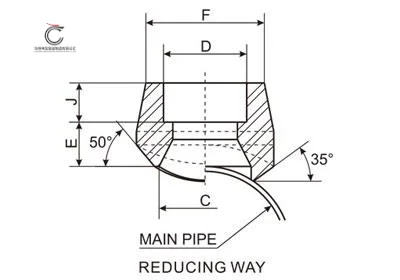

Branch Connection fittings (also known as O'lets) are fittings which provide an outlet from a larger pipe to a smaller one (or one of the same size). The main pipe onto which the branch connection is welded is usually called the Run or Header size. The pipe to which the branch connection provides a channel is usually called the Branch or Outlet size. Branch connections are in all sizes, types, bores, and classes, in a wide range of stainless steel, chrome-moly, and other alloys.

Connection type: welded,threaded,BW,SW

Surface: Carbon steel and alloy steel with yellow print, black print, oil, or zinc.

Application: Petroleum, chemical, machinery, electric power, shipbuilding, papermaking, construction, etc

Shenlong Forge fittings meeting the 100% reinforcement requirement of applicable piping codes i.e. ASME B31.1, B31.3, B31.4 and B31.8. They also meet the MSS-SP-97 Standard- 'Integrally Reinforced Forged Branch Outlet Fittings'.Shenlong Forge fittings meeting the 100% reinforcement requirement of applicable piping codes i.e. ASME B31.1, B31.3, B31.4 and B31.8. They also meet the 2001 edition of MSS-SP-97 Standard- 'Integrally Reinforced Forged Branch Outlet Fittings.

Types of Branch Connection Fittings:

Weldolet is the most common of all branch connections and is welded onto the outlet pipe. The ends are bevelled to facilitate this process, and therefore the weldolet is considered a butt-weld fitting. Weldolet's are designed to minimize stress concentrations and provide integral reinforcement.

Sockolet utilizes the basic Weldolet® however the branch affixes by way of a socket inside the olet. The bore matches the outlet bore, and the existence of a counter bore roughly the size of the OD of the outlet provides a socket where the pipe can sit, facilitating installation and welding. The Sockolet® is considered a socket fitting, and manufactured in 3000#, 6000# and 9000# classes.

Threadolet utilizes the basic Weldolet® however the branch affixes by way of a thread just inside the top of the olet. The bore matches the outlet bore, and the existence of this threading facilitates installation, as no welding is necessary. The Thredolet is considered a threaded fitting, and manufactured in 3000# and 6000# classes.