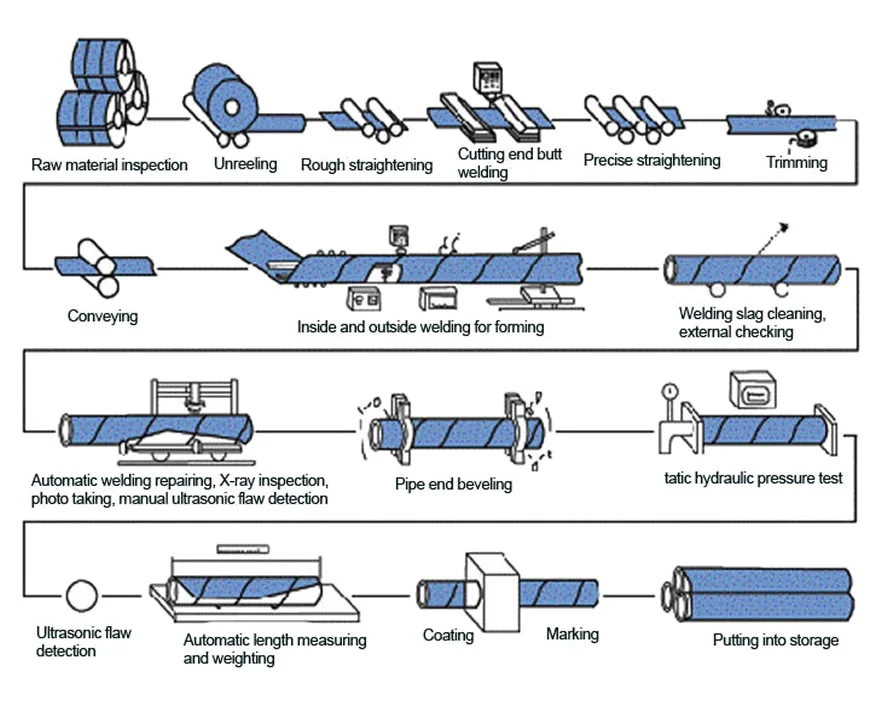

Spiral Submerged-arc Welded steel pipe technological process

Spiral welded pipe production by submerged arc method is based on using tandem welding technique for joining inside and outside coil edges, which have been trimmed and beveled by carbide milling for high-quality weld structure.

Spiral Submerged-arc Welded steel pipe technological process

There are nine modernized product lines in our company with a yield capacity of 1000 thousand tons of B-X80 steel pipe of φ219-φ3200mm, WT5-30mm.

Listing some notes You must know

Oiled marking: Steel after passing was oiled to prevent corrosion, and according to user requirements for making.

Leveling Milling: The flat steel anvil machine so that the original curl, and then through the edge milling machine for two-sided steel milling, so as to meet the requirements of the plate width, plate edge parallelism, and groove shape.

Shear molding: The steel plate production line along the outer edge of the spiral curl into a tube.

Butt cut: Double-sided submerged arc welding using advanced technology for pre-welding, internal welding, and outside welding. The welded steel pipe uses a plasma-foot cut to specification length.

Cangzhou Shenlong Pipe Manufacturing Co., Ltd. is a high-tech enterprise specializing in the manufacture and sales of straight-seam welded pipe and spiral steel pipe. The main products of the company are oil and gas bushing, tubing, pipeline pipe, pile pipe, structural pipe, etc., with an annual design capacity of 100,000 tons. The company's products execute API SPEC 5CT, API SPEC 5L, FM 1630, UL 852, JIS G3444, JIS G3452, ASTM A53/A53M, AS/NZS 1163, AS/NZS 1074, AS/NZS 1396, EN10217, EN10219, EN10255, and GB/T9711, GB/T3091, and other domestic and foreign standards. Products are exported to overseas markets and widely used in petroleum, natural gas, solar energy, shipbuilding, automobile, chemical, environmental protection, boiler, fire protection, water conservancy, electrical industry, machinery and equipment, steel structure, construction, and other industries.