Product List

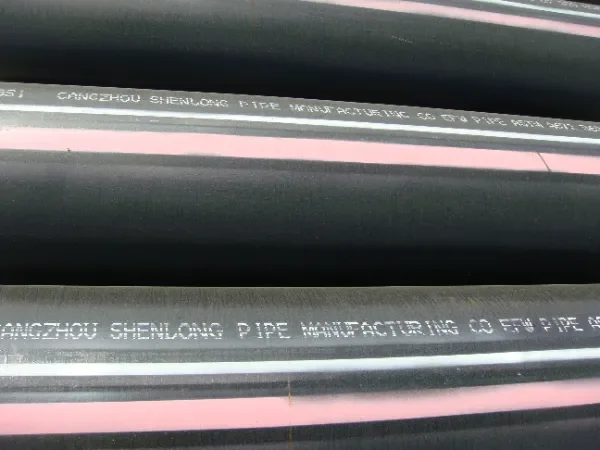

Straight Seam Steel Pipe

Product name: Straight seam steel pipe, LSAW welded pipe, Welded steel pipe, welded pipe, SAW steel pipe, Welded Steel Tube, Hollow pipe, seam welded pipe, Carbon Steel Welded Pipe, Carbon Steel Pipe, Erw welded steel pipe, rolled and welded

Materials: S195T, GR.B, X42, X52, X60, CC60, CC70, ST35, ST52, S235JR, S355JR, SGP, STP G370, STPG410, GR2 etc.

Standard: API 5L, ASTM A53, A515, A672, A500, A252, BS1387, EN10255, EN10217, JIS G3454 etc.

SHENLONG PIPE produce an extensive selection of welded steel pipe including ERW, HFI, EFW, LSAW, DSAW and UOE type carbon steel pipe along with their respective flanges and fittings.

Welded steel pipe manufacturing process is simple, efficient, and more varieties of different specifications, equipment, less capital, but the general strength of less than seamless.Since the 1930s, with high-quality strip steel rolling production and the rapid development of welding and inspection technology, continuously improving the quality of welds, welded steel pipe specifications increasing and more and more areas instead of non-pipe joints.

Straight seam steel pipe

Welding type of welded pipe: ERW, SAWL, EFW, HFW.

Materials: S195T, GR.B, X42, X52, X60, CC60, CC70,ST35, ST52, S235JR, S355JR, SGP, STP G370,STP G410, GR2 etc.

Standard: API 5L,ASTM A53, A515, A672, A500,A252,,BS1387, EN10255, EN10217,JIS G3454 etc.

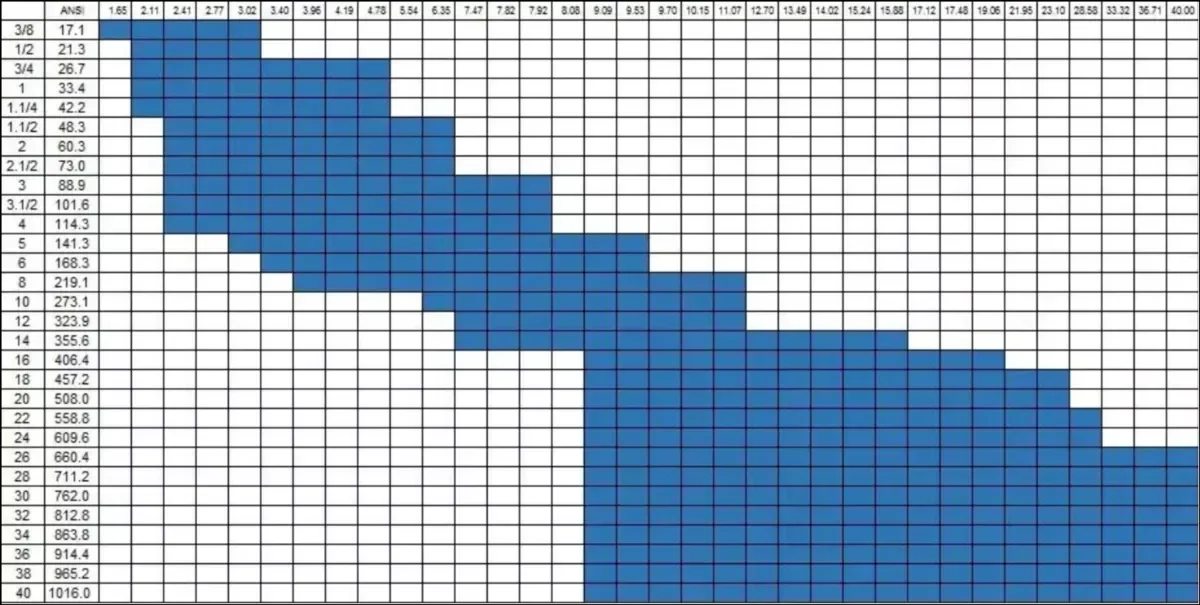

Straight seam steel pipe specification:

Outer diameter: 1/4”-48” (13.7mm-1422.2mm).

Wall thickness: 1.2mm-60mm.

Length: 2m-14m.

End: plain end, beveled end, thread, coupling, plastic cap in the both end, pipe clamp.

Surface: oiled, black painted or varnish, galvanized, 3PE, FBE, or other epoxy coating.

Inspection: hydrostatic testing, ultrasonic testing, eddy current testing, magnetic particle testing, impact testing, hardness testing, etc.

Application: petroleum, chemical, electric power, water, construction, pipelines, etc.

Straight seam steel pipe advantages

Shenlong straight seam steel pipe has uniform wall thickness and 100% non-destructive testing of the weld seam. We have short delivery time, over 30,000 tons in stock all year round and a complete range of pipe specifications; we have 6 testing procedures to ensure that the quality of the products leaving the factory are all qualified; we also have 10 production lines and fast delivery time.

Straight seam steel pipe quality inspection:

1. Our factory has its own "experimental testing center".CNAS Laboratory Accreditation Certificate

2.Control quality strictly.The first pass is the quality inspection on the production line,The second pass is full inspection of the production quality .

3.We have got internationally recognized certificates, ISO, CE, LR,Philippine certificate,also support third-party testing,as SGS, BV, ect.

Straight Seam Steel Pipe feature

Welded pipe from steel plate welding into the round pipe, divided into high frequency resistance welded pipe (ERW welded pipe), straight seam arc welding pipe (LSAW), spiral welded pipe.Electrical engineering with “SC”, can be used as water gas pipe can also be used as threading pipe, relatively thick.

Ends of Pipes

For the ends of pipes are 3 standard versions available.

Plain Ends (PE)

Threaded Ends (TE)

Beveled Ends (BE)

The PE pipes will generally be used for the smaller diameters pipe systems and in combination with Slip On flanges and Socket Weld fittings and flanges.

Straight Seam Steel Pipe Technical Data

Straight seam steel pipe is a steel pipe with the weld seam parallel to the longitudinal direction of the steel pipe. Usually divided into metric electric welded steel pipe, electric welded thin-walled pipe, transformer cooling oil pipe and so on. The production process of straight seam welded pipe is simple, the production efficiency is high, the cost is low, and the development is fast. The strength of the spiral welded pipe is generally higher than that of the straight seam welded pipe. However, compared with the same length of straight seam pipe, the length of the weld is increased by 30~100%, and the production speed is lower.

According to the production process, straight seam steel pipes can be divided into high frequency straight seam steel pipes and submerged arc welded straight seam steel pipes. Submerged arc welded straight seam steel pipes are divided into UOE, RBE, JCOE steel pipes according to their different forming methods.

The main processing methods of straight seam steel pipe are:

Forged steel: A press working method that uses the reciprocating impact force of a forging hammer or the pressure of a press to change the billet into the shape and size we need.

Extrusion: It is a processing method in which the steel is placed in a closed extrusion tube, and pressure is applied at one end to extrude the metal from the specified die hole to obtain a finished product with the same shape and size. It is mostly used for the production of non-ferrous metal materials. .

Rolling: A pressure processing method in which a steel metal billet is passed through a gap (various shapes) of a pair of rotating rolls, and the cross-section of the material is reduced and the length is increased due to the compression of the rolls.

Drawing steel: It is a processing method that draws a rolled metal billet (shape, pipe, product, etc.) through a die hole to reduce the cross-section and increase the length.

For cold working.

Straight seam steel pipes are mainly used in tap water engineering, petrochemical industry, chemical industry, electric power industry, agricultural irrigation, and urban construction.

For liquid transportation: water supply, drainage.

For gas transportation: gas, steam, liquefied petroleum gas.

For structure: for piling pipe, for bridge; for wharf, road, building structure, etc.

How to select high quality straight seam steel pipe?

How to remove rust from straight seam steel pipe?

Straight seam submerged arc welding steel pipe production technology

Two production processes of straight seam steel pipes

Precautions in the maintenance process of straight seam steel pipes

Comparison of Spiral Steel Pipe and Straight Seam Steel Pipe

The manufacturing process of high frequency straight seam steel pipe

What inspection should straight seam steel pipe go through before leaving factory?

Welding process of straight seam steel pipe

Common welding methods of straight seam steel pipe

What are the commonly used inspection methods of straight seam steel pipe?

Production technology of straight seam steel pipe

What should we pay attention to when cutting straight seam steel pipe?

What matters needing attention when large mouth straight seam steel pipe installation?

Straight seam steel pipe expansion technology

Derusting methods of straight seam steel pipe

Precautions for using straight seam steel pipe

How much pressure can large-diameter thick-walled straight seam steel pipes?

Straight seam steel pipe vs spiral steel pipe

Surface treatment method of straight seam steel pipe

How to solve the existence of magnetism in thick-walled straight seam steel pipe

Non-destructive testing of straight seam steel pipes

Principle and processing method of straight seam steel pipe

The differences between straight seam steel pipe and seamless steel pipe

Knowledge of straight seam steel pipe

Straight seam steel pipe length measurement and surface treatment

Straight seam steel pipe out of the furnace and back to the furnace

Straight seam steel pipe about the method

Straight seam steel pipe structural design features

The role of straight seam steel pipe in different fields

How to clean the straight seam steel pipe

Temperature problems in the production of straight seam steel pipes

How to distinguish between straight seam steel pipe and seamless steel pipe?

How are straight seam steel pipes produced?

Forming method of straight seam steel pipe

Method for heat treatment of straight seam steel pipe

What are the manufacturing processes of straight seam steel pipes?

How to avoid the fracture of straight seam steel pipe?

What is straight seam steel pipe

Drawing for straight seam steel pipe