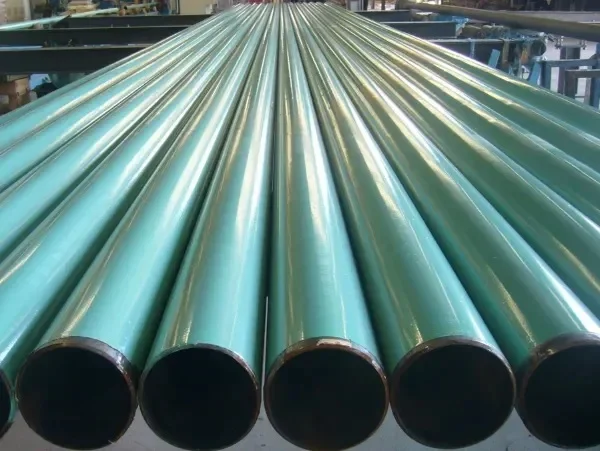

What do you need to pay attention to when installing epoxy coated steel pipe?

Epoxy coated steel pipe is a commonly used pipe material with excellent corrosion resistance and high strength and is widely used in petroleum, chemical, natural gas, and other industries. When installing, you need to pay attention to the following points:

1. Ambient temperature and humidity

The installation environment of Epoxy coated steel pipe should be kept dry, clean, and well-ventilated. The ambient temperature should be above 5°C and the humidity should be below 85%. If the ambient temperature is too low or the humidity is too high, it will affect the quality and adhesion of the coating, and even cause the coating to fall off.

2. Surface treatment

Before installation, the surface of the steel pipe should be treated, including dusting, cleaning, and grinding. Dusting should be thorough, reaching Sa2.5 level or above, cleaning should use a non-alkaline cleaning agent, grinding should make the surface smooth, free of burrs, rust, and oil stains, etc.

3. Coating construction

Coating construction should be carried out in accordance with the requirements of the paint manufacturer, including stirring, dilution, spraying, etc. of the paint. The coating should be uniform, smooth, and free of bubbles and sagging, and the thickness of the coating should meet the design requirements. Before the coating is dry, the surface of the steel pipe should be protected from contamination and mechanical damage.

4. Pipe connection

When connecting pipes, attention should be paid to the butt joint quality and tightness of the pipes. The joints of the pipes should be treated with anti-corrosion treatment, such as applying anti-corrosion tape or coating anti-corrosion paint. The thread of the connection should be coated with a sealant to ensure tightness. During the installation process, care should be taken to prevent the pipe from being subjected to bending, stretching, and other forces, so as to avoid problems such as cracking and peeling of the coating. At the same time, it is necessary to prevent the pipeline from being corroded by chemical substances, such as acid and alkali.

5. Pipeline transportation and storage

During pipeline transportation and storage, the surface of steel pipes should be protected from mechanical damage and contamination. The pipes should be stored in a dry, ventilated, and light-proof place, avoiding direct sunlight and rain. The storage time should not be too long, so as not to affect the coating quality.

In a word, the installation of Epoxy coated steel pipe needs to pay attention to aspects such as ambient temperature and humidity, surface treatment, coating construction, pipeline connection, and pipeline transportation and storage to ensure the quality and service life of the pipeline.

How to Distinguish the Quality of Epoxy Coated Steel Pipes?

What does epoxy-coated steel pipe storage pay attention to?

Characteristics and advantages of epoxy coating