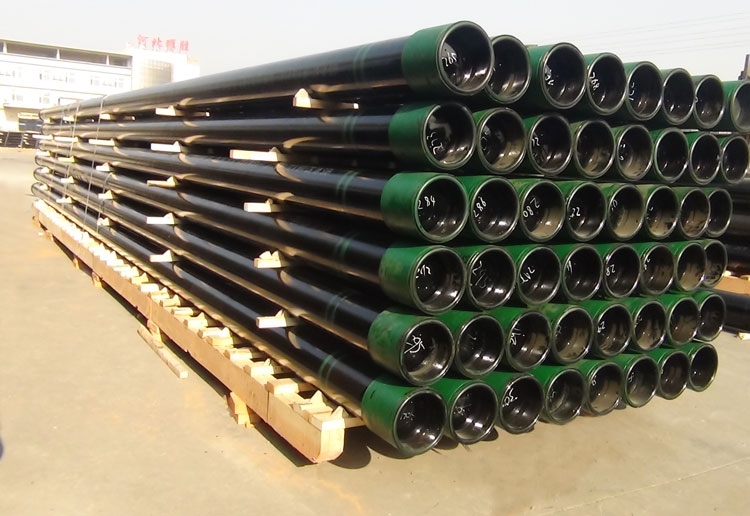

A Guide to API 5CT Casing Pipes

Casing pipes are crucial components in the oil and gas industry, serving primarily to protect and support the borehole during drilling and subsequent operations. The API 5CT standard, governed by the American Petroleum Institute, specifies the technical delivery conditions for steel casings used in oil wells. Cangzhou Shenlong's API5CT casing pipes, designed to transport oil, natural gas, and other fluids, are recognized for their robustness, especially under extreme conditions of high temperature and high pressure. These casings are available in various lengths (R-1, R-2, and R-3) and materials such as Grades B, X42, X46, X56, X65, and X70, ensuring versatility and reliability. Before dispatch, each casing undergoes rigorous tests—including flattening, tensile, and impact tests—to guarantee its quality and performance in the field.

Understanding API 5CT Casing Pipes

Definition and Function of Casing Pipes

Casing pipes are steel pipes used in oil and gas wells to stabilize the wellbore and ensure the safe extraction of natural resources. They prevent the well walls from collapsing, isolate different layers of the subsoil to avoid fluid migration, and protect groundwater from contamination.

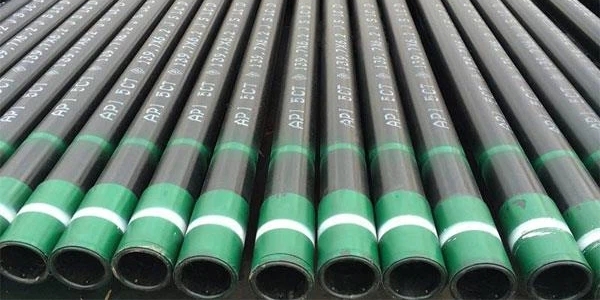

Key Specifications of API 5CT

The API 5CT standard specifies the requirements for the manufacture of steel casings. Here are some key specifications:

- Specification range: Outside Diameter (OD) from 114.3 mm to 508 mm (4 1/2" to 20”).

- Materials: Common grades include H40, J55, K55, N80-1, N80-Q, L80-1, L80-9Cr, L80-13Cr, P110, Q125.

- Executive standards: API 5CT, GB (Chinese Standard), ISO11960, and GOST (Russian Standard).

- Length: Available in R1, R2, and R3, which correspond to different lengths suited for various drilling depths.

- Testing: Includes Non-Destructive Testing (NDT) and other API 5CT and 5B related testing rules.

- Type: Typically seamless pipe, ensuring structural integrity and durability under extreme conditions.

Types of API 5CT Casing Pipes

Classification Based on Material

- API 5CT J55: An entry-level grade, generally used in shallow wells and low-pressure environments.

- API 5CT K55: Comparable to J55 but with enhanced mechanical properties and resistance.

- API 5CT N80: Suitable for deeper drilling environments with higher pressure conditions.

- API 5CT L80: Has higher toughness than N80; available in different corrosion-resistant classes (L80-9Cr, L80-13Cr for CO2 and H2S-rich environments).

- API 5CT P110: A high-strength material for extreme conditions, offering higher pressure resistance.

Classification Based on Thread Type

- External Upset (EU): Features an external shoulder providing a tight seal and strong joint.

- Non-Upset (NU): Has a smooth connection with no external shoulder, used in less demanding conditions.

- Integral Joint (IJ): Designed for special applications, featuring a threaded connection integrated into the pipe body.

Selection Criteria for API 5CT Casing Pipes

Geographical and Geological Considerations

Selection depends on the location's topography and geology, affecting which casing grade and type are most suitable.

Well Conditions and Depth

Deeper wells with higher pressures require stronger, more durable casing materials like P110, while shallower wells may use J55 or K55.

Environmental Factors

The presence of corrosive elements like CO2 or H2S in the environment necessitates the use of corrosion-resistant materials like L80-13Cr.

Regulatory Compliance

Compliance with local, national, and international regulations and standards is crucial to ensure safety and environmental protection.

Installation and Maintenance

Pre-installation Inspection and Preparation

Before installation, each casing pipe must undergo a thorough inspection to check for defects such as cracks, dents, or corrosion. Preparation involves ensuring the compatibility of casing sizes and threading, and treating surfaces with protective coatings if necessary.

Installation Procedures

The installation of casing pipes involves:

- Lowering the casing: Carefully lowering the casing into the wellbore to prevent structural damage.

- Thread lubrication: Applying thread compound to protect and seal the connections.

- Casing connection: Joining sections of casing together using the specified threading technique, ensuring a secure and leak-proof fit.

- Cementing: Once the casing is in place, cement is pumped into the space between the casing and the borehole wall to permanently set the casing and isolate formation layers.

Post-installation Maintenance and Monitoring

After installation, regular maintenance and monitoring are crucial. This includes:

- Pressure testing: To ensure the integrity of the seal and connections.

- Corrosion monitoring: Regular inspections for signs of corrosion or wear.

- Integrity logs: Using specialized tools to assess the condition and integrity of the casing over time.

Quality Assurance and Inspection

API 5CT Certification Process

The API 5CT certification ensures that casing pipes meet stringent industry standards for quality and safety. This process includes reviewing the manufacturer's production processes, quality control measures, and product compliance with API standards.

Quality Control Measures During Manufacturing

Manufacturers must adhere to rigorous quality control protocols, including:

- Material selection: Only high-quality steel is used, sourced from trusted suppliers.

- Manufacturing oversight: Continuous monitoring during manufacturing to maintain strict adherence to API specifications.

- Batch testing: Testing samples from each batch for mechanical strength, chemical composition, and other critical properties.

Inspection Protocols and Standards

Inspection protocols include dimensional checks, visual inspection, and non-destructive testing methods such as ultrasonic or radiographic testing to identify internal and external defects.

Case Studies and Best Practices

Real-world Applications of API 5CT Casing Pipes

Case studies from various regions have shown that API 5CT casing pipes are effective in diverse drilling environments. For example, in offshore oil drilling in the North Sea, casing pipes have successfully withstood high-pressure and corrosive environments due to their robust design and material selection.

Lessons Learned from Successful Projects

One key lesson is the importance of proper casing selection based on specific geological conditions. Incorrect casing selection can lead to failures, increased costs, and safety risks.

Best Practices for Maximizing Performance and Longevity

Best practices include:

- Regular training for installation crews: Ensuring that those involved in installation are up-to-date with the latest techniques and standards.

- Use of premium connections: Employing advanced threading and sealing technologies to enhance the reliability of casing installations.

- Adherence to installation guidelines: Following manufacturer and industry guidelines meticulously to avoid common pitfalls.

Future Trends and Developments

Innovations in Casing Pipe Technology

Advancements in materials science are leading to the development of more durable and corrosion-resistant casings. Innovations such as smart casing pipes with embedded sensors are emerging, providing real-time data on well conditions.

Emerging Industry Standards and Regulations

As environmental and safety standards become stricter, the oil and gas industry is likely to see tighter regulations regarding casing installation and monitoring. This will drive improvements in casing quality and installation practices.

Potential Challenges and Opportunities

Challenges include adapting to low carbon emission standards and managing the costs associated with implementing advanced technologies. However, these challenges also present opportunities for innovation and for improving the efficiency and environmental footprint of drilling operations.

In Sum

API 5CT casing pipes are fundamental to the successful operation of oil and gas wells, providing essential structural integrity and protection. Adhering to rigorous standards, thorough installation procedures and diligent maintenance are crucial to maximizing their performance and longevity. With ongoing advancements in technology and stricter industry regulations, the future of casing pipes looks promising. Innovations are continuously enhancing their functionality and environmental sustainability, meeting the evolving needs of the industry. The commitment to quality assurance and learning from past projects further ensures that these vital components meet the high demands of the oil and gas sector, thus safeguarding resources and the environment alike.