Exploring the Benefits and Uses of Epoxy Coated Steel Pipe

What exactly is epoxy coated steel pipe for?

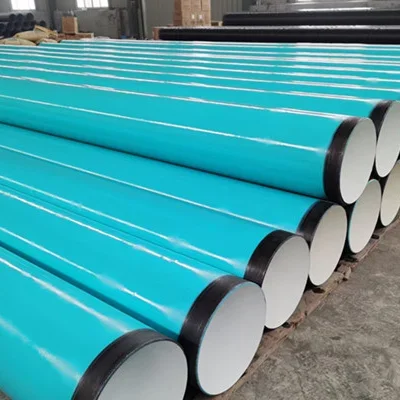

· Due to their outstanding durability and resistance to corrosion, epoxy coated steel pipe is a crucial part of contemporary infrastructure and is utilized extensively in many fields and applications. These pipes are normally made of premium steel and coated in an epoxy resin coating to shield them from the corrosive effects of moisture, chemicals, and the environment.

· The epoxy coating serves as a barrier, keeping corrosive chemicals from coming into direct contact with the steel surface and increasing the pipes' lifespan. Additionally, this coating improves the pipe's resistance to abrasion, making it appropriate for conveying abrasive materials like sewage and slurries.

· They are often utilized in industrial processes, oil and gas pipelines, water supply and wastewater systems, and other applications where corrosion resistance is important. Additionally, these pipes' ease of installation and maintenance lowers total operational expenses.

What are the types of coating?

Selecting the proper coating is essential for preventing corrosion in steel pipes and increasing lifespan. Four popular alternatives stand out from the various coatings: FBE (Fusion Bonded Epoxy), liquid epoxy, epoxy powder, and epoxy coal tar. Each has distinct qualities and uses that make them indispensable elements in corrosion prevention.

1. Epoxy Fusion Bonded:

Steel pipes can be coated with FBE coating, a thermosetting epoxy powder coating, using a fusion process. Consequently, the steel surface is strongly adhered to an extremely robust and chemically resistant layer. Oil, gas, and water pipelines, as well as those in the automotive and marine sectors, frequently employ FBE coatings. They are perfect for underground and underwater applications because they have good adhesion and corrosion resistance.

2. The liquid epoxy

Solvent-based coatings known as liquid epoxy are commonly applied in two-component systems. These coatings are renowned for their adaptability and simplicity, making them appropriate for shop and field coating. They have good steel adhesion and are frequently used in industrial and maritime settings where resistance to chemicals and abrasion is essential.

3. Epoxy powder

Dry and epoxy powder coatings are electrostatically applied to steel pipes and then heated during curing. This procedure produces a robust shielding covering that is impervious to UV rays, chemicals, and corrosion. Due to their outstanding endurance and aesthetic appeal, epoxy powder coatings are commonly employed in the construction, automotive, and aerospace sectors.

4. Epoxy Coal Tar:

The corrosion resistance of epoxy and the waterproofing qualities of coal tar are combined in epoxy coal tar coatings. These coatings are frequently employed in maritime applications, such as ship hulls and offshore constructions, where they offer a strong defence against seawater and challenging environmental factors. Underground pipes and tanks are also covered with epoxy coal tar coatings.

Epoxy Coated Steel Pipe: The Ultimate Solution for Corrosion Resistance

· They have become the best defence against corrosion, the tenacious foe of metal infrastructure. Epoxy coated steel pipes have become essential for assuring long-term durability and dependability when pipelines, water supply systems, and industrial buildings are exposed to harsh environmental conditions and aggressive chemicals.

· A precisely placed coating of epoxy resin protection is at the core of these pipes, covering the steel surface. This epoxy coating acts as a strong barrier, protecting the steel from substances that might cause corrosion, including moisture, chemicals, and even abrasives. This indicates that these pipes can withstand the worst circumstances without rusting or degrading.

· They are used in various applications, including oil and gas pipelines, chemical processing facilities, water and wastewater systems, etc. They are the preferred option for transferring various fluids and chemicals, preserving the integrity of crucial infrastructure thanks to their capacity to withstand corrosion and abrasion.

· Epoxy coated steel pipe drastically lowers maintenance and operating expenses. These pipes have a long service life with little maintenance needed, unlike uncoated steel pipes, which frequently need repair and replacement due to corrosion-induced damage. For businesses and communities, this results in significant savings.

· They lessen the possibility of spills and leaks, which might have disastrous environmental effects. Fewer resources are used in the manufacture and repair of pipes because of their longer lifespan, helping to achieve sustainability goals.

Why is epoxy coated steel pipe important in various industries?

Epoxy coated pipes are indispensable in many sectors and are used in a wide range of applications. Their value stems from their capacity to handle major issues that companies deal with, such as corrosion resistance, cost-effectiveness, and sustainability.

· Longevity:

Epoxy coated steel pipe has a longer service life than uncoated steel pipes in terms of longevity. This durability is essential in fields like municipal water supply and wastewater treatment, where buried or submerged tubes are constantly exposed to moisture and chemicals. Their robustness reduces the necessity for regular replacements and maintenance, which results in significant cost savings.

· Versatility:

These pipes are used in various fields, including agriculture, construction, energy generation, and others. They offer versatility in design and construction and are appropriate for above-ground and underground installations.

Epoxy coated steel pipes are generally inexpensive, cutting labour costs and project duration. They are, therefore, a desirable option for businesses wishing to simplify their processes.

· Cost-Effectiveness:

Epoxy coated pipes' long-term cost-effectiveness is apparent, even though their initial cost may be greater than other alternatives. They are a smart investment for companies looking to maximize their budgets because of the lowered maintenance and replacement expenses and the decreased downtime.

Conclusion:

Not only do they guarantee the efficient running of vital infrastructure, but they also support sustainability initiatives by reducing environmental effects. Epoxy coated steel pipe remains a vital solution for their many complex demands as industries continue to develop. Compared to other producers, Cangzhou Shenglong Pipe Manufacturing Co., Ltd. stands out for our dedication to employing only the best components. To guarantee that the finished product meets the highest requirements, the firm only uses raw materials from reliable suppliers and employs stringent quality control procedures throughout manufacturing.