Seamless Solutions: The Power of Epoxy Pipe Lining

The maintenance of infrastructure is pivotal for ensuring the longevity and efficiency of utility systems worldwide. Neglect in this crucial area can lead to significant disruptions and costly repairs. Epoxy pipe lining emerges as a revolutionary solution in the arsenal of infrastructure maintenance. This technique not only extends the life of piping systems but also enhances their performance without the need for extensive excavation. The purpose of this discussion is to explore the manifold benefits and applications of epoxy pipe lining. At our factory, which boasts an "experimental testing center" accredited by CNAS, quality is paramount. With rigorous dual-stage quality inspections and certifications like ISO, CE, LR, and more, we adhere to international standards, ensuring reliability and excellence in every product.

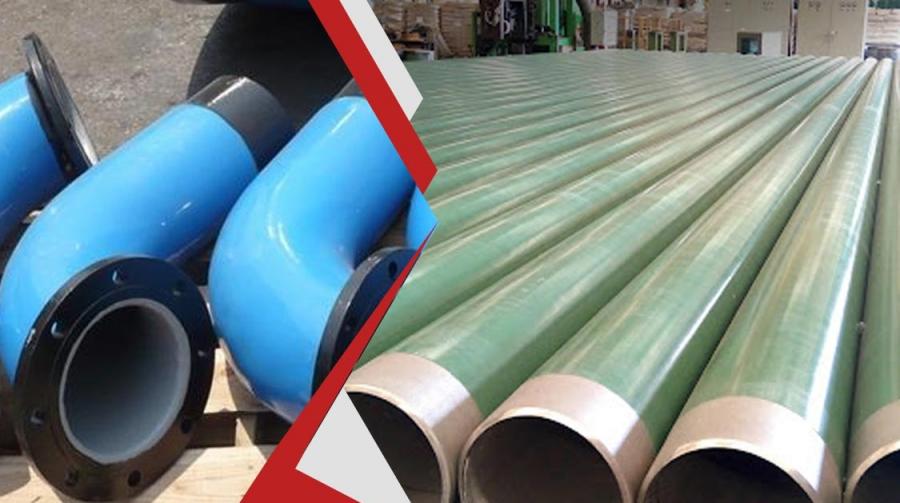

Understanding Epoxy Pipe Lining

Definition and Basic Principles

Epoxy pipe lining is an innovative method used to rehabilitate old or damaged pipes by creating a new, seamless inner surface within the existing pipe. This is accomplished through the application of an epoxy resin, which cures to form a strong, corrosion-resistant lining.

How Epoxy Pipe Lining Works

The process begins with the thorough cleaning of the interior of the pipe to remove any debris, corrosion, or buildup. Once cleaned, an epoxy resin is introduced into the pipe, typically using air pressure. The resin coats the inner surface and is then left to cure, hardening into a robust new pipe within the old structure.

Comparison with Traditional Pipe Repair Methods

Traditional methods of pipe repair often involve digging up and replacing the old pipe, which can be disruptive and expensive. In contrast, epoxy lining is non-invasive, requiring only minimal access points to feed the resin. This method is significantly less disruptive and can be completed more quickly than traditional repair methods.

Advantages of Epoxy Pipe Lining

Durability and Longevity

Epoxy linings are highly durable and resistant to a variety of chemicals and abrasive materials, significantly extending the lifespan of pipes by preventing future corrosion and leaks.

Cost-effectiveness

The cost of digging up and replacing pipes, especially in urban areas, can be exorbitant. Epoxy pipe lining provides a cost-effective alternative by minimizing labor, time, and materials.

Minimal Disruption to Daily Operations

Since the entire process is less invasive, it can often be completed with little to no disruption to daily operations in homes, businesses, and public services. This is especially beneficial in busy or critical areas where traditional excavations could cause significant disturbances.

Environmentally Friendly

Epoxy pipe lining is an environmentally favorable option as it reduces the need for extensive excavation, thereby decreasing the carbon footprint associated with traditional pipe replacement. Additionally, it helps prevent potential contaminants from leaking into the surrounding soil and water systems.

Versatility in Application

The versatility of epoxy pipe lining is evident as it can be applied to various types of pipes including water, sewer, and gas lines, regardless of material—whether it's copper, steel, or plastic.

Applications of Epoxy Pipe Lining

Residential Plumbing Systems

In residential settings, epoxy lining is used to repair common issues like leaks and root intrusion without the need for extensive landscape disruption.

Commercial and Industrial Pipelines

Epoxy pipe lining is ideal for larger scale operations such as those found in commercial and industrial environments, where downtime can equate to significant financial loss.

Municipal Water and Sewer Systems

Municipal systems benefit greatly from epoxy linings as they provide a less disruptive, cost-effective solution for maintaining extensive underground piping networks.

Specialty Applications

Epoxy linings are also used in more specialized settings, such as pipes carrying chemicals or other corrosive substances, due to their resistance to a wide range of chemical agents and high temperatures.

Case Studies and Success Stories

Example Projects Demonstrating the Effectiveness of Epoxy Pipe Lining

One notable project involved the rehabilitation of a century-old water main in a bustling city center. The epoxy lining was applied within a single day, avoiding the need for extensive road closures and community disruption, effectively restoring the pipe to a like-new condition.

Testimonials from Satisfied Clients

Clients, ranging from municipal authorities to commercial property managers, have praised the epoxy pipe lining process for its efficiency and minimal impact. One facility manager noted, "The process was fast, and the results were immediate. We avoided a major construction project and extensive downtime."

Highlighting Specific Challenges Addressed and Solutions Provided

In another case, a manufacturing plant faced significant operational downtime due to pipe leaks. Epoxy pipe lining was implemented as a swift solution, addressing leaks and vulnerabilities without halting production, showcasing the method's capability to provide solutions under tight constraints.

Considerations and Limitations

Compatibility with Different Pipe Materials

While epoxy is versatile, its adherence and effectiveness can vary based on the pipe material. Proper assessment and material testing must precede application to ensure compatibility, particularly with older or heavily deteriorated pipes.

Preparation and Installation Requirements

The success of epoxy lining heavily depends on the preparation phase, which involves thorough cleaning and possibly repairing major defects before the epoxy application. This preparation is crucial to ensure the lining adheres properly and performs as expected.

Potential Limitations in Extreme Conditions or Specialized Situations

Epoxy linings may not be suitable for pipes that operate under extreme temperatures or pressures, or for pipes carrying certain chemicals that could compromise the integrity of the epoxy resin. Each scenario requires a detailed evaluation to determine the viability of using epoxy lining.

Future Trends and Innovations

Emerging Technologies in Epoxy Formulations

Research is ongoing into new epoxy formulations that can cure faster, adhere better, and resist a wider range of chemical agents. These developments aim to broaden the applicability and effectiveness of epoxy pipe lining.

Advancements in Application Techniques

Technological advancements are also being made in the methods of applying epoxy. Innovations such as robotic lining techniques and improved resin injection systems are making the process even less invasive and more precise.

Predictions for the Future of Epoxy Pipe Lining in Infrastructure Maintenance

The future of epoxy pipe lining looks promising with potential expansions into more diverse types of infrastructure and further minimization of impact on daily operations. As urban areas continue to grow and the demand for efficient, non-disruptive maintenance solutions increases, epoxy pipe lining is set to play a pivotal role in the maintenance of modern infrastructures.

CONCLUSION

Epoxy pipe lining stands out as a transformative solution in infrastructure maintenance, offering a blend of efficiency, cost-effectiveness, and minimal disruption. Its ability to extend the lifespan of piping systems while adhering to environmental standards underscores its significance in modern maintenance strategies. With ongoing advancements in materials and application techniques, epoxy pipe lining is poised to address even more complex and diverse infrastructure challenges. This innovative method not only reinforces the reliability of existing systems but also exemplifies the power of modern engineering solutions in preserving critical infrastructure seamlessly.