Guide to ERW Steel Tube: A Dive Into

Cost-effectiveness, high weld seam security, and versatility are ERW steel tube’s benefits. Cold-forming and high-frequency electric welding are ERW steel tube manufacturing process that results in a strong and reliable product suitable for various applications. As a leading supplier of ERW steel tubes, Cangzhou Shenlong Pipe Manufacturing Co., Ltd. offers expertise, quality assurance, and a customer-centric approach. You can ensure successful project outcomes and long-term performance by choosing the right supplier and understanding the advantages of ERW steel tubes.

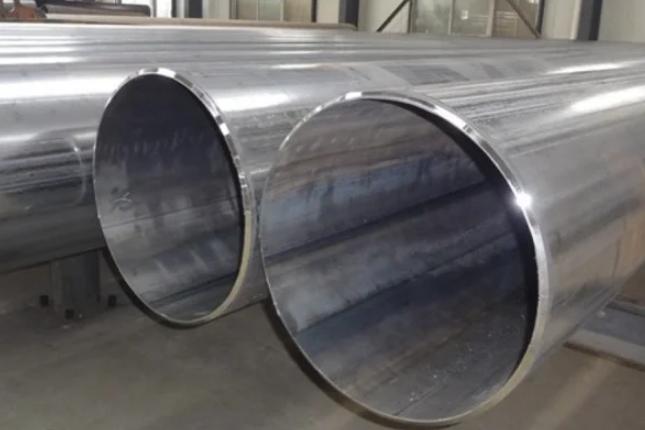

What is ERW Steel Tube?

ERW, or Electric Resistance Welded steel tubes, are a type of steel tubing manufactured through a specific welding process. These tubes are created by cold-forming a flat steel coil into a cylindrical shape and then welding the edges together using high-frequency electric resistance. This method ensures that the resulting tube has a strong and uniform weld seam, making it suitable for various engineering and construction applications.

The Current Market Needs and Status

Growing Demand in Engineering and Construction

ERW (Electric Resistance Welded) steel tubes are increasingly becoming a critical component in various engineering and construction applications. The demand for ERW steel tubes is driven by their versatility, cost-effectiveness, and the growing needs of industries such as construction, chemical processing, and water treatment. With the rapid pace of infrastructure development globally, the need for reliable and durable steel tubes continues to rise.

Market Dynamics and Trends

The market for ERW steel tube is characterized by its responsiveness to fluctuations in raw material prices and technological advancements. Currently, there is a strong emphasis on sustainability and cost reduction, which drives the demand for high-quality ERW tubes. This trend is particularly evident in regions with large-scale construction and industrial projects, where efficient and high-performing materials are crucial.

Supply Chain Considerations

One of the significant aspects affecting the ERW steel tube market is the supply chain dynamics. The global supply chain for steel is complex, with varying degrees of availability and pricing based on geopolitical and economic factors. As such, companies are increasingly seeking reliable suppliers who can offer consistent quality and timely delivery, which is where suppliers like Cangzhou Shenlong Pipe Manufacturing Co., Ltd. come into play.

Solutions Provided by ERW Steel Tubes

Versatility Across Applications

ERW steel tubes offer a wide range of solutions across different applications due to their customizable specifications. These tubes can be used in various fields, including construction, chemical industries, water treatment, and agricultural irrigation. Their ability to be tailored to specific requirements, such as wall thickness and diameter, makes them a versatile choice for engineers and manufacturers.

Cost-Effective Alternatives

One of the primary solutions ERW steel tubes offer is their cost-effectiveness. The manufacturing process of ERW tubes involves cold forming steel coils into cylindrical shapes, which is less expensive compared to other welding methods. This cost efficiency makes ERW tubes a preferred choice for projects where budget constraints are a significant consideration.

High-Quality Performance

ERW steel tubes are known for their high weld seam security and uniformity in quality. The high-frequency resistance welding process used in their production ensures that the weld is as strong as the base metal, providing excellent mechanical strength and reliability. This makes ERW tubes suitable for high-pressure and demanding applications.

Benefits of ERW Steel Tubes

Superior Mechanical Properties

ERW steel tubes are distinguished by their superior mechanical properties. The welding process ensures that the tubes have a high strength-to-weight ratio, making them ideal for structural and load-bearing applications. Their resistance to high pressure and impact is particularly beneficial in industries such as oil and gas, where durability is crucial.

Customizable Specifications

The ability to customize ERW steel tubes in terms of diameter, wall thickness, and length offers significant advantages. This flexibility allows for precise fitting and installation in various engineering projects, reducing the need for additional modifications and improving overall project efficiency.

Enhanced Surface Treatments

ERW steel tubes come with various surface treatment options, such as oiling, black paint spraying, galvanizing, and epoxy coatings. These treatments enhance the tubes' resistance to corrosion and environmental damage, extending their lifespan and reducing maintenance costs. This is particularly valuable in harsh or corrosive environments.

Applications of ERW Welded Steel Pipes

Industrial and Chemical Applications

ERW welded steel pipes are extensively used in industrial and chemical applications due to their strength and durability. They are ideal for transporting chemicals, gases, and other fluids, where reliability and resistance to pressure are critical.

Construction and Infrastructure

In construction and infrastructure projects, ERW steel pipes play a crucial role in structural support, water treatment, and agricultural irrigation. Their adaptability to various sizes and coatings makes them suitable for diverse construction needs, from highway billboards to bridge supports.

Oil and Gas Conveyance

The oil and gas industry relies heavily on ERW steel pipes for conveying fluids and gases across long distances. The high-frequency resistance welding process ensures that the pipes can withstand the pressures and stresses encountered in these applications, making them a dependable choice for this sector.

ERW Welded Steel Pipe Specifications

Dimensions and Variability

ERW welded steel pipes come with a range of specifications to accommodate different needs. The outer diameter ranges from 1/4” to 26” (13.7mm to 660.4mm), and the wall thickness can vary from 10mm to 100mm. The length of the pipes typically ranges from 3 meters to 14 meters, allowing for flexibility in application.

Surface Treatments

To ensure durability and performance, ERW steel pipes can be treated with various surface coatings. Options include oiling, black paint spraying, galvanizing, and advanced coatings like 3PE and FBE epoxy. These treatments are designed to enhance corrosion resistance and extend the service life of the pipes.

Quality Control Measures

The quality control of ERW steel pipes involves multiple inspection stages. From production line checks to full-scale inspections, the company employs rigorous testing methods to ensure that each pipe meets high standards. This includes hydrostatic and ultrasonic testing, among others, to verify the pipes' integrity and performance.

Why Choose Cangzhou Shenlong Pipe Manufacturing Co., Ltd.

Expertise and Quality Assurance

Cangzhou Shenlong Pipe Manufacturing Co., Ltd. is renowned for its expertise in the production of ERW steel tubes. With a robust quality assurance process in place, the company ensures that every product meets stringent international standards. Their in-house experimental testing center, accredited by CNAS, verifies the quality and performance of their tubes through various testing methods, including hydrostatic, ultrasonic, and impact testing.

Comprehensive Certifications

The company's commitment to quality is reflected in their array of internationally recognized certifications, including ISO, CE, and LR. Additionally, they support third-party testing from reputable organizations like SGS and BV. These certifications underscore their dedication to maintaining high standards and providing reliable products to their clients.

Customer-Centric Approach

Cangzhou Shenlong Pipe Manufacturing Co., Ltd. takes pride in its customer-centric approach. They offer customized solutions to meet specific project requirements and ensure safe and seaworthy packaging for export. Their attention to detail and commitment to customer satisfaction make them a preferred supplier for various industries worldwide.

Conclusion

ERW steel tubes represent a versatile, cost-effective solution for a wide range of engineering and construction applications. Their high-quality performance, customizable specifications, and various surface treatments make them an attractive option for industries requiring reliable and durable materials. Cangzhou Shenlong Pipe Manufacturing Co., Ltd. stands out as a leading supplier, offering expertise, comprehensive certifications, and a customer-centric approach to meet the diverse needs of the market. As the demand for ERW steel tubes continues to grow, choosing the right supplier and understanding the benefits of these tubes will be crucial for successful project outcomes.