Factory Price & High-Quality Mild Steel MS Square Pipe

Mild steel (MS) square pipes, which are indispensable components within both the construction and manufacturing industries, hold a critical place due to their inherent properties of high tensile strength, reduced weight, and exceptional resistance to corrosion. These characteristics make the pipes a versatile and reliable option for a broad spectrum of applications. This blog aims to explore in detail the distinctive features, numerous applications, and substantial advantages of MS square pipe, with a particular emphasis on the comprehensive solutions offered by Cangzhou Shenlong Pipe Manufacturing Co., Ltd., a prominent supplier in the global market.

Features of Mild Steel MS Square Pipe

Exceptional Strength and Long-Lasting Durability

Renowned for its remarkable sturdiness, mild steel square tubing stands as the material of choice for robust industrial applications, particularly those involving heavy-duty usage. The outstanding strength-to-weight ratio enables these pipes to bear substantial loads without the risk of deformation, ensuring performance that is both reliable and long-lasting. This feature enhances their suitability for both structural and fabrication-oriented projects.

Mild steel square pipes, owing to their superior mechanical attributes, are capable of sustaining heavy weights and pressures with ease. This capacity contributes significantly to their widespread implementation in frameworks, load-bearing scaffolding, and other structural systems. Their resistance to environmental stresses further underlines their utility in harsh industrial conditions, where durability is a crucial requirement.

Superior Corrosion Resistance and Low-Maintenance Characteristics

Among the most prominent qualities of MS square pipe is their corrosion-resistant nature. When treated appropriately, mild steel develops a protective oxide layer that effectively shields it from oxidation and rust, thus extending its operational lifespan. This property makes it highly suitable for use in environments that experience consistent exposure to moisture or outdoor conditions.

In addition to their corrosion resistance, these pipes are exceptionally easy to maintain. Routine cleaning and periodic inspections help ensure that they remain in optimal working condition, providing years of reliable service. The minimal maintenance needs result in lower operational costs, positioning MS square pipes as a cost-efficient solution for projects that demand long-term performance.

Lightweight and Flexible in Design

Despite being recognized for their robust strength, MS square pipe is considerably lighter in weight compared to other conventional materials. This advantageous combination of lightness and structural integrity renders them highly efficient in both construction and manufacturing sectors that demand sturdy yet manageable materials. Furthermore, the adaptability of MS square pipes in terms of fabrication and engineering allows them to be easily cut, drilled, and shaped to meet specific project requirements.

The lightweight nature of these pipes also reduces both transportation expenses and installation complexities, a factor that boosts their popularity across various sectors, ranging from machinery construction to the development of architectural frameworks.

Broad Applications of MS Square Pipe

Industrial Construction Applications

In the realm of industrial construction, MS square pipe is commonly employed in the development of structural frameworks, support beams, and stabilizing systems. These pipes are crucial in providing the necessary stability required to construct large-scale buildings and infrastructures without compromising safety standards. The uniform structure of square tubing ensures that load distribution is even, which is essential for the stability of multi-story buildings, storage facilities, and heavy industrial infrastructure.

For contractors and engineers, the reliability of MS square pipes translates into consistent performance across varied construction scenarios. Whether the project involves constructing high-rise towers, bridges, or industrial factories, MS square pipes contribute significantly to the overall strength and longevity of the infrastructure. Their ease of processing allows for cost-effective customization, aligning with specific architectural and engineering standards.

Machinery Construction, Racks, and Storage Containers

The construction of machinery and equipment, which often necessitates materials capable of withstanding substantial pressure, weight, and harsh environmental conditions, frequently incorporates MS square pipes. These pipes meet the stringent demands of machinery construction by offering the required strength and resilience essential for components such as racks and storage containers.

The uniform shape of MS square pipes also ensures superior stability, an essential factor in constructing stable storage racks, durable equipment frameworks, and reliable industrial machinery. Furthermore, their corrosion-resistant properties ensure that these components remain operational, even under challenging conditions. The simplicity of machining and welding makes it easier for manufacturers to create custom machinery and storage containers with precise dimensions and specifications.

Engineering and Fabrication Projects

Within the engineering and fabrication sectors, MS square pipe serves as an integral component. Their ability to be welded and formed with ease makes them an optimal choice for custom engineering projects. Whether the goal is to construct vehicle frames, specialized machine components, or complex architectural metalwork, these pipes offer practical and highly efficient solutions.

The smooth surface of mild steel square tubing is another key attribute appreciated by fabricators, as it simplifies the processes of painting, coating, and finishing. This adaptability enables the material to meet both functional and aesthetic requirements across various projects. Moreover, MS square pipe can be reused or repurposed, adding further value by contributing to sustainability initiatives and cost savings over time.

Technical Specifications and Industry Standards

Dimensions and Tolerance Standards

MS square pipe is available in a wide array of dimensions, making it versatile enough to suit a multitude of applications. The outer dimensions (OD) can vary from 10mm to 500mm, while the wall thickness (WT) ranges between 0.5mm and 50mm. Additionally, these pipes can be produced in custom lengths, spanning from 0.3 meters to 18 meters, depending on the specific requirements of the project. This extensive range of sizes ensures that mild steel square pipes can accommodate projects of any scale or complexity.

For small structural components or large-scale industrial constructions, the broad selection of dimensions allows engineers and architects to choose the correct size and thickness to meet precise structural and load-bearing demands. This versatility ensures that MS square pipes offer greater flexibility in terms of design and practical applications.

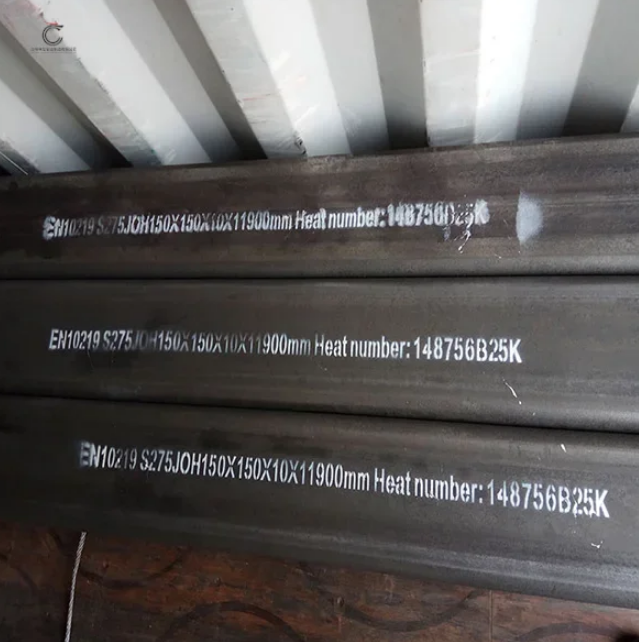

International Compliance and Standards

To guarantee the quality, reliability, and safety of MS square pipes, these materials are manufactured in accordance with strict international standards. These include, but are not limited to, ASTM A500, ASTM A53, EN10210, EN10219, JIS G3466, BS1387, and BS6323, each ensuring compliance with essential quality requirements such as mechanical properties, dimensional precision, and durability.

By adhering to these rigorous standards, Cangzhou Shenlong Pipe Manufacturing Co., Ltd. ensures that its MS square pipes consistently perform at high levels across industries. This adherence also ensures that the products meet the regulatory standards of global markets, making them a reliable choice for international construction and manufacturing projects.

Customizable End Finishing Options

To meet a wide range of construction and fabrication needs, MS square pipes are available with customizable end finishes. Commonly, these pipes feature square-cut ends with burrs removed, resulting in a smooth, clean surface that facilitates easier handling and assembly. This finish also enhances the efficiency of welding processes, eliminating the need for further treatment and ensuring a polished final product.

In structural applications, the square-cut end finish improves precision during installation, making it an ideal choice for projects where accuracy is paramount. For industrial or engineering ventures, the burr-free finish reduces the risk of injury during handling, ensuring both safety and efficiency during the project lifecycle.

Why Choose Cangzhou Shenlong Pipe Manufacturing Co., Ltd.?

Expertise in Producing High-Quality MS Square Pipes

Cangzhou Shenlong Pipe Manufacturing Co., Ltd. stands as a recognized leader in the production and supply of premium-quality mild steel square pipes. The company’s extensive experience and proficiency in manufacturing square steel tubing that meets international standards allow them to cater to the diverse needs of their customers. With state-of-the-art production facilities and rigorous quality control protocols, the company guarantees that each pipe undergoes stringent testing and inspection for optimal performance.

Competitive Factory Pricing and Global Distribution Network

One of the foremost advantages of choosing Cangzhou Shenlong is the company’s ability to offer factory-direct pricing without compromising quality. By streamlining their production processes and sourcing raw materials strategically, they provide clients with MS square pipe that represents exceptional value. Whether for small-scale or large-scale projects, customers benefit from a cost-effective solution that maintains high standards of performance.

Additionally, with a robust global distribution network, the company is fully equipped to handle international orders. With a commitment to timely delivery and dependable logistics, Cangzhou Shenlong ensures that customers around the world receive their materials on schedule, maintaining project timelines with efficiency.

Conclusion

Mild steel square pipe is fundamental in a wide array of industries due to their impressive strength, corrosion resistance, and adaptability. With extensive applications ranging from construction to custom fabrication, these pipes are essential to numerous sectors. Cangzhou Shenlong Pipe Manufacturing Co., Ltd., as a top supplier in the industry, provides high-quality, competitively priced products that adhere to global standards and fulfill the specific needs of their clients. Whether you are undertaking a major construction project or require materials for specialized fabrication, Cangzhou Shenlong’s MS square pipes offer the reliability and performance necessary to ensure success.