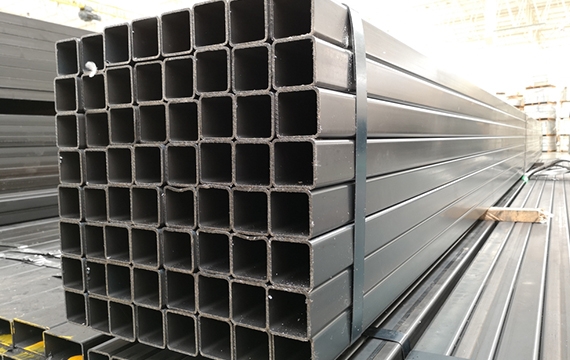

The Majesty of MS Square Tube

The MS (Mild Steel) Square Tube is a vital component in construction and engineering projects. It is a welded hollow square-cut steel tube, available in grades like A513 or A500 Grade B, chosen based on size and wall thickness. Its square shape offers enhanced rigidity and strength, making it ideal for structural applications, fabrication, manufacturing, and repairs. The versatility of MS Square Tube allows for customization through cutting, forming, machining, and welding, ensuring precise specifications are met. Compared to other steel shapes like angles or channels, the square tube configuration provides superior strength and rigidity. Its importance lies in its ease of use, adaptability, and reliability across various construction and engineering endeavors.

Structural Properties of MS Square Tube

Cross-sectional Design and Dimensions

The MS Square Tube features a distinctive square cross-sectional design, providing uniformity in shape and dimensions throughout its length. This uniformity ensures predictable performance and facilitates precise fitting and joining in construction projects. Standard dimensions range from small sizes suitable for light-duty applications to larger sizes capable of bearing heavy loads.

Strength and Durability Compared to Other Materials

MS Square Tubes exhibit exceptional strength and durability, making them a preferred choice over alternative materials such as aluminum or plastic. Mild steel, renowned for its robustness, offers superior resistance to bending, twisting, and other forms of deformation, ensuring structural integrity even under demanding conditions. This durability translates to long-lasting performance, reducing the need for frequent maintenance or replacement.

Versatility in Applications

The versatility of MS Square Tubes extends across a wide spectrum of applications in construction and engineering. From supporting frameworks and infrastructure to serving as components in architectural designs, these tubes find utilization in diverse projects. Their adaptability allows for customization through various fabrication techniques, including cutting, welding, and bending, catering to specific project requirements with ease.

Applications in Construction

Frameworks and Support Structures

MS Square Tubes play a fundamental role in constructing frameworks and support structures for buildings, bridges, and other infrastructure projects. Their high strength-to-weight ratio and stability make them ideal for creating sturdy frameworks capable of withstanding heavy loads and adverse environmental conditions. Common applications include column supports, roof trusses, and framework reinforcement.

Architectural Designs and Aesthetics

Beyond their structural function, MS Square Tubes contribute to the aesthetic appeal of architectural designs. Their clean lines and geometric shape offer architects and designers creative freedom to incorporate modern and innovative elements into their projects. Whether used as decorative accents, railing systems, or facades, these tubes add visual interest and architectural flair to both interior and exterior spaces.

Load-Bearing Capacities

One of the key attributes of MS Square Tubes is their exceptional load-bearing capacity, making them indispensable in supporting heavy loads in construction projects. Whether used as beams, columns, or braces, these tubes provide reliable support to structures, ensuring safety and stability. Their ability to distribute loads evenly helps prevent structural failures and enhances the overall performance of the construction.

Cangzhou Shenlong's Manufacturing Process for Rectangular/Square Hollow Sections

Cangzhou Shenlong employs a meticulous manufacturing process to produce high-quality rectangular and square hollow sections. The process involves the following steps:

Rectangular/Square Hollow Section Manufacturing Process

Coils are first selected for the production process. These coils are then fed through a series of dies, where they undergo shaping to attain the desired rectangular or square profile. The shaped sections are welded from the inside to finalize their structural integrity and form.

Types of Hollow Sections Produced

Cold Formed Square Hollow Section: Manufactured through a cold forming process to achieve precise dimensions and excellent surface finish. Cold Formed Rectangular Hollow Section: Similar to the square counterpart, but designed in rectangular shapes to meet specific structural requirements. Hot Finish Square Hollow Section: Produced through a hot finishing process, ensuring enhanced mechanical properties and surface finish. Hot Finish Rectangular Hollow Section: Utilizing hot finishing techniques to create rectangular hollow sections with superior strength and aesthetics.

Specifications and Standards

|

Specification |

Description |

|

A500 Gr-B |

ASTM standard for cold-formed welded and seamless carbon steel structural tubing, encompassing round, square, and rectangular hollow sections. |

|

A513 |

Specification ensuring high weldability, commonly utilized in structural applications for various industries including bridges, buildings, automotive, and appliances. |

Through adherence to these stringent manufacturing processes and standards, Cangzhou Shenlong ensures the production of rectangular and square hollow sections that meet the highest quality and performance standards.

Environmental Sustainability

Recyclability and Eco-friendliness of Mild Steel

Mild steel, the primary material used in MS Square Tubes, offers exceptional recyclability, bolstering environmental sustainability. At the end of a product's lifecycle, mild steel can be recycled without compromising its quality or structural integrity. This recyclability diminishes the demand for raw materials and reduces waste, positioning MS Square Tubes as an environmentally conscious choice for construction and engineering projects.

Energy Efficiency in Production and Transportation

The production process of MS Square Tubes prioritizes energy efficiency, aiming to minimize energy consumption and carbon emissions. Leveraging advanced manufacturing technologies and optimized processes, the energy footprint associated with tube production is significantly reduced. Furthermore, the lightweight nature of MS Square Tubes facilitates efficient transportation, curtailing fuel consumption and greenhouse gas emissions during transit.

Longevity and Minimal Maintenance Requirements

MS Square Tubes boast exceptional longevity and durability, necessitating minimal maintenance and replacement. Their robust construction and resistance to corrosion and degradation ensure prolonged service life, mitigating the environmental impact linked with frequent repairs and replacements. By demanding minimal maintenance throughout their lifecycle, MS Square Tubes actively contribute to resource conservation and environmental sustainability.

Case Studies

Examples of Iconic Structures Utilizing MS Square Tube

MS Square Tubes feature prominently in numerous iconic structures worldwide, spanning from skyscrapers and bridges to stadiums and cultural landmarks. These tubes play a pivotal role in supporting and enhancing architectural marvels, exemplified by structures like the Burj Khalifa in Dubai, the Millau Viaduct in France, and the Beijing National Stadium (Bird's Nest) in China. These examples underscore the versatility and reliability of MS Square Tubes in monumental projects.

Success Stories of Engineering Feats Achieved with MS Square Tube

MS Square Tubes have played a pivotal role in realizing engineering feats across diverse industries and applications. These tubes have facilitated remarkable advancements in aerospace, automotive, or infrastructure projects. Success stories include the construction of lightweight yet robust aircraft frames, efficient automotive chassis designs, and innovative structural solutions for challenging environments.

Testimonials from Professionals in the Construction and Engineering Industries

Professionals within the construction and engineering sectors attest to the unmatched performance and versatility of MS Square Tubes. Architects, engineers, and contractors recognize these tubes' critical role in realizing their visions, delivering structural integrity, and ensuring project success. These testimonials underscore the confidence placed in MS Square Tubes for their reliability, efficiency, and contribution to the sustainability of construction projects.

Innovations and Future Prospects

Advances in MS Square Tube Technology

Ongoing research and development efforts continue to propel advancements in MS Square Tube technology, enhancing their mechanical properties, durability, and sustainability. Innovations such as high-strength steel alloys, corrosion-resistant coatings, and improved manufacturing processes are expanding the capabilities and applications of MS Square Tubes.

Integration with Emerging Construction Methodologies

MS Square Tubes are increasingly integrated into emerging construction methodologies like prefabrication and modular construction. Their adaptability, ease of fabrication, and compatibility with automated manufacturing processes make them well-suited for off-site fabrication and assembly. This integration streamlines construction processes, reduces waste, and enhances project efficiency.

Potential for Enhancing Sustainability and Performance

The future of MS Square Tubes holds significant potential for further enhancing sustainability and performance across diverse industries. Innovations in material science, recycling technologies, and sustainable manufacturing practices aim to reduce environmental impact while improving structural efficiency and longevity. By capitalizing on these advancements, MS Square Tubes will remain at the forefront of sustainable construction and engineering solutions.

In Closing

The magnificence of MS Square Tube is evident in its structural strength, eco-friendliness, and adaptability across diverse fields. With its sturdy construction, remarkable durability, and role in conserving resources, MS Square Tube showcases engineering brilliance. Evolving with technological progress and inventive techniques, it retains its pivotal position in shaping contemporary landscapes. Its enduring importance and steadfast dependability epitomize the fusion of robustness, sustainability, and innovation in construction and engineering.