Oil Country Tubular Goods: Key Players and Trends

Are you aware that the entire stability and success of a drilling operation often depend on just one critical component—Oil Country Tubular? These essential pipes serve as the structural backbone of oil and gas extraction activities, making it possible to maintain the integrity and stability of a well throughout the drilling process. But what exactly are Oil Country Tubular Goods, and why have they become such an irreplaceable asset in the energy industry? In this comprehensive guide, we’ll delve into the significance, various types, and emerging trends surrounding Oil Country Tubular, while also providing valuable insights on what to consider when selecting the most suitable Oil Country Tubular products for your specific drilling needs.

An In-Depth Understanding of Oil Country Tubular

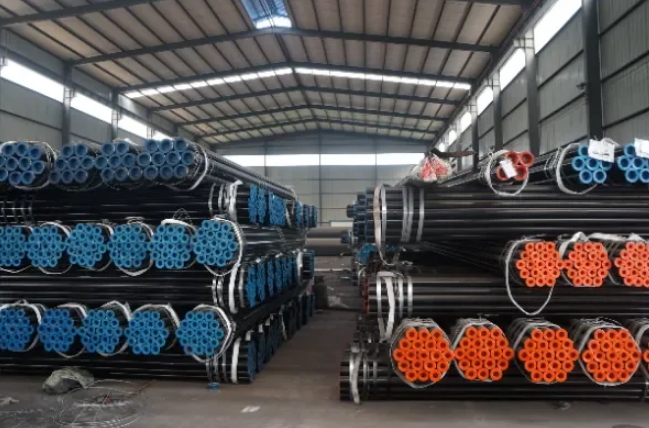

Oil Country Tubular Goods, encompass a wide array of pipes designed to facilitate and support drilling operations in the oil and gas industry. This specialized category includes several subtypes such as casing, tubing, and drill pipes, each fulfilling a distinct role in maintaining good stability and ensuring efficient transportation of extracted resources. Oil Country Tubular products are constructed from diverse materials, including high-strength steel grades like L245, L360, J55, K55, N80, L80, and P110, all engineered to withstand the demanding, high-pressure environments encountered during drilling operations.

Key Variants of Oil Country Tubular Goods

Casing

Casing is installed within the wellbore to fortify the walls and prevent any potential collapse. Several forms of casing exist—ranging from surface casing to intermediate casing, as well as production casing—each serving a specific purpose in upholding well integrity and isolating different pressure zones effectively.

Tubing

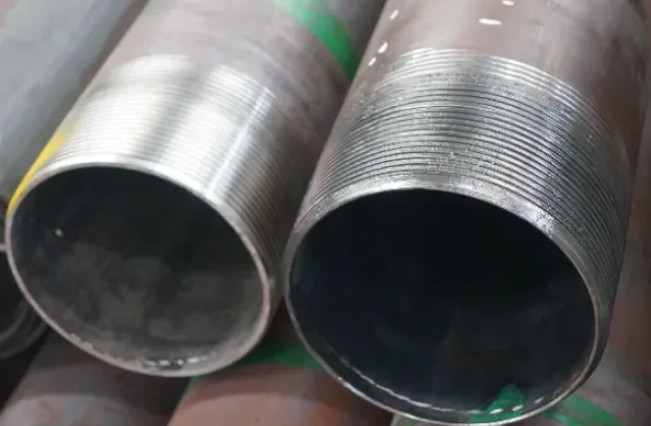

Tubing is inserted within the casing to transport extracted resources, such as oil or gas, from the base of the well to the surface. Depending on its dimensions and intended usage, tubing can be categorized into non-upset tubing (NU), external upset tubing (EU), or integral joint tubing (IJ), each suited to different operational scenarios.

Drill Pipe

Drill pipes are employed to transmit the necessary torque and rotational force to drill into the earth's subsurface. Subject to extreme mechanical stresses, these pipes must adhere to strict quality standards to ensure optimal safety and operational efficiency.

Critical Roles of Oil Country Tubular in Drilling Operations

Oil Country Tubular Goods are indispensable in virtually every phase of drilling operations, from initial exploration and testing to final production and extraction. Below, we outline three pivotal roles that Oil Country Tubular products play in the industry:

Ensuring Well Integrity and Stability

Casing provides essential structural support to the well, effectively preventing the collapse of the wellbore and guaranteeing the safety of the drilling team. This role is especially crucial in geologically unstable formations or areas with high-pressure zones, where the risk of wellbore failure is markedly elevated.

Facilitating Resource Transport

Once the well is drilled and the casing is securely set, tubing takes on the task of transporting the extracted resources—whether it be oil, gas, or water—up to the surface. High-quality tubing ensures the efficient and secure movement of these resources, minimizing the risk of leakage or contamination.

Ensuring Safety and Environmental Protection

The structural integrity of Oil Country Tubular products is fundamental in maintaining well control and preventing potentially catastrophic blowouts, which could lead to severe environmental damage. High-quality Oil Country Tubular products, such as those manufactured in accordance with API Spec 5CT standards, are designed to withstand extreme pressure and temperature fluctuations, thereby contributing to safer drilling operations.

Emerging Innovations and Trends in the Oil Country Tubular Market

As the oil and gas sector continues to evolve, so too do the products and technologies associated with it. The following are some of the key trends that are currently shaping the future of Oil Country Tubular Goods:

Advanced Material Engineering

Driven by the need for superior performance, manufacturers are developing new materials that offer enhanced strength, corrosion resistance, and durability. The use of advanced steel alloys and cutting-edge coating technologies has significantly improved the longevity and operational efficiency of Oil Country Tubular products, even in the most challenging environments.

Non-Destructive Testing (NDT) and Stringent Quality Control

Quality assurance remains a cornerstone in the production of Oil Country Tubular. To meet increasingly stringent industry standards, many manufacturers are adopting sophisticated non-destructive testing methods, such as ultrasonic and electromagnetic testing, to identify even the slightest imperfections. Companies like Cangzhou Shenlong Pipe Manufacturing Co., Ltd. utilize a multi-tier inspection protocol that includes in-house testing as well as independent, third-party assessments to guarantee the dependability of their products.

Digitalization and Integration of Smart Technologies

The integration of digital solutions—such as smart sensors and real-time data monitoring—into Oil Country Tubular production and usage is revolutionizing the industry. These advancements allow operators to continuously monitor pipe conditions and performance metrics, reducing the likelihood of unexpected failures and enabling more proactive maintenance strategies.

Selecting the Ideal Oil Country Tubular Goods: Key Considerations

Choosing the right Oil Country Tubular products is essential for the success and safety of any drilling project. Here are several key considerations to keep in mind:

Material and Grade

Selecting the appropriate material and grade is critical, as it determines the pipe’s ability to withstand the conditions of the specific well. Higher-grade materials like P110 or L80 are often chosen for deeper wells or those with higher pressure and temperature requirements.

Size and Specification

The dimensions of the casing and tubing should be selected based on the well’s diameter and the anticipated flow rate of the extracted resources. Standard sizes for line pipes typically range from 21.3 mm to 2032 mm, while tubing and casing generally vary between 1 1/2" and 20" in diameter.

Connection Type

Connection types—such as threaded and coupled (T&C) or integral joint (IJ)—play a crucial role in determining the overall integrity and performance of Oil Country Tubular products. The selection of the appropriate connection type will depend on the specific application and the operational conditions encountered.

Cangzhou Shenlong Pipe Manufacturing Co., Ltd.: Leading the Way in Oil Country Tubular Supply

With over two decades of experience in the oil and gas sector, Cangzhou Shenlong Pipe Manufacturing Co., Ltd. has earned a reputation as a premier supplier of top-quality Oil Country Tubular products. The company’s portfolio includes seamless casing pipes, API 5L line pipes, and gas pipelines, all produced in compliance with internationally recognized standards such as API Spec 5L and API Spec 5CT.

Stringent Quality Assurance and Comprehensive Testing

Equipped with state-of-the-art production facilities and an in-house experimental testing center accredited with the CNAS Laboratory Certification, Cangzhou Shenlong enforces a rigorous quality control regimen. This process includes both real-time production monitoring and extensive product testing to ensure every batch meets the highest standards of safety and reliability.

Global Reach and Trusted Market Presence

Having executed projects across multiple continents and built a robust reputation for excellence, Cangzhou Shenlong Pipe Manufacturing Co., Ltd. has firmly established itself as a leading player in the Oil Country Tubular market. The company’s products are renowned for their outstanding quality, durability, and adherence to global industry standards.

Conclusion

Oil Country Tubular Goods is a cornerstone of the oil and gas industry, ensuring the structural integrity and operational efficiency of drilling activities. From casing to tubing and drill pipes, each Oil Country Tubular component plays a vital role in the success and safety of good operations. As the sector continues to progress, innovations in material engineering, quality control, and digital technologies will pave the way for the next generation of Oil Country Tubular solutions. For businesses seeking a reliable partner in the Oil Country Tubular supply chain, Cangzhou Shenlong Pipe Manufacturing Co., Ltd. offers a comprehensive range of high-quality products designed to meet the diverse needs of modern drilling projects.