Top SS Pipe Supplier: Who’s Leading the Market

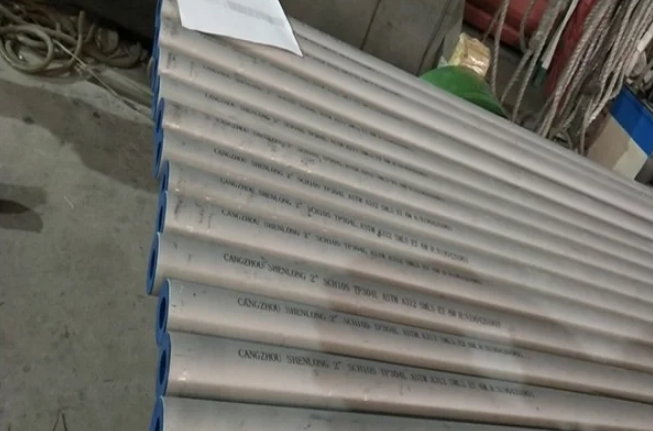

Have you considered the extent to which the choice of an SS pipe supplier can shape the outcome and overall success of your project? Stainless steel seamless pipes, which are integral components in multiple industrial sectors, serve as the foundation for building robust systems. However, establishing a partnership with a leading supplier is not just about product quality—it’s a critical factor that influences timely deliveries, cost efficiencies, and long-term project viability. But with an overwhelming number of options in the market, determining the ideal supplier for your specific needs can be a daunting task. In this comprehensive guide, we delve into the importance of selecting a certified SS pipe supplier, such as Cangzhou Shenlong Pipe Manufacturing Co., Ltd., and how this decision can play a pivotal role in the realization of your project goals.

Advantages of Engaging with a Certified Stainless Steel Pipe Supplier

When it comes to influencing the performance of your business operations, the role of a certified stainless steel pipe supplier cannot be overstated. Below, we outline the critical advantages of collaborating with an accredited supplier and how it can elevate your operational standards.

1. Assurance of Quality and Compliance with Industry Norms

A certified supplier’s adherence to recognized industry standards, including but not limited to ASTM A312, A213, and DIN2462, guarantees that their products consistently meet the rigorous quality requirements necessary for industries such as petrochemical, power generation, and oil and gas. By adhering to these standards, suppliers like Cangzhou Shenlong Pipe Manufacturing Co., Ltd., provide a broad portfolio of high-grade products, such as TP304, TP316L, and TP321 seamless pipes, ensuring their materials perform optimally even in the most challenging environments.

2. Expansive Product Line and Tailored Solutions

Partnering with an established SS pipe supplier grants access to an extensive array of stainless steel grades and dimensions—ranging from 1/8 inch to 26 inches in outer diameter, with various wall thickness options. Such flexibility is indispensable for addressing diverse application requirements, whether it’s for high-temperature applications, structural integrity, or specialized mechanical uses. Moreover, experienced suppliers are equipped to handle customized specifications, offering tailored solutions that precisely align with your project’s unique parameters.

3. Enhanced Cost-Efficiency and Operational Stability

One of the subtle yet impactful benefits of choosing a reliable supplier is the mitigation of hidden costs that arise from product defects or untimely deliveries. Through stringent quality controls and streamlined manufacturing processes, certified suppliers minimize the occurrence of inconsistencies and performance issues. Consequently, this translates into reduced downtime, fewer replacements, and significant long-term cost savings, making your operations more sustainable and financially viable.

Analyzing the Role of SS Pipe Suppliers in Critical Industrial Applications

In the context of industrial applications, stainless steel seamless pipes are not mere conduits—they are fundamental to the infrastructure of various sectors, from chemical processing to automotive manufacturing. A reputable SS pipe supplier, like Cangzhou Shenlong Pipe Manufacturing Co., Ltd., plays an instrumental role in enabling these projects by providing materials that are not only high-performing but also capable of enduring extreme environmental conditions.

1. Meeting Stringent Specifications in the Oil and Gas Industry

The oil and gas sector is characterized by its stringent material specifications, which demand exceptional resistance to high pressures, elevated temperatures, and corrosive environments. Seamless stainless steel pipes, free from welding seams and joints, are ideal for such applications. A reputable supplier ensures that these pipes consistently deliver robust performance, mitigating risks associated with material failure and enhancing operational safety and reliability.

2. Ensuring Operational Safety in Chemical and Fertilizer Manufacturing

Chemical processing and fertilizer production involve exposure to harsh chemicals, abrasives, and thermal variations. Stainless steel grades such as TP310S and TP316L, which are known for their superior resistance to chemical reactions, offer durability and reliability in these conditions. Certified suppliers maintain strict quality standards to provide products that meet the mechanical and corrosion resistance properties required for these critical applications, thereby safeguarding the operational integrity of these facilities.

3. Supporting Infrastructure and Construction Requirements

Infrastructure projects often demand versatile stainless steel pipes for applications such as water treatment, fire safety systems, and structural support. Reliable suppliers offer an array of seamless pipe specifications, ensuring that the materials align with precise project requirements in terms of dimensions, wall thicknesses, and mechanical properties. This ensures the overall safety and durability of the constructed infrastructure.

The Concealed Costs of Opting for the Wrong SS Pipe Supplier

The decision to partner with a particular SS pipe supplier should not be guided by price alone. Opting for a non-certified supplier based solely on initial cost savings can lead to substantial hidden expenses that may negatively impact your project’s profitability and execution timeline.

1. Substandard Product Quality and Associated Safety Risks

Non-certified suppliers may employ suboptimal materials or bypass critical quality control steps, leading to products that lack the desired wall thickness consistency, tensile strength, or corrosion resistance. Such defects can cause pipeline leaks, ruptures, or, in worst-case scenarios, catastrophic system failures—especially when used in high-pressure or high-temperature environments.

2. Escalated Maintenance and Frequent Replacements

Low-quality materials often result in faster wear and tear, necessitating frequent replacements and maintenance interventions. These direct costs are compounded by the impact on operational efficiency, as unexpected maintenance can disrupt production schedules and extend project timelines.

3. Legal Complications and Non-Compliance Issues

Using non-compliant materials poses not only operational risks but also legal and regulatory challenges. For industries subject to strict compliance requirements, such as food processing or pharmaceuticals, failure to meet material standards can result in costly legal penalties and damage to the company’s reputation.

Strategies for Establishing a Long-Term Partnership with Your Stainless Steel Pipe Supplier

Cultivating a long-term, collaborative relationship with your SS pipe supplier can yield considerable benefits for your business. Below are some strategies to ensure a strong partnership:

1. Set Clear Communication Channels and Expectations

Open and transparent communication is vital for any business relationship. Clearly communicate your project requirements, including product specifications, delivery schedules, and quality expectations. This ensures that the supplier understands your objectives and is prepared to meet or exceed these expectations.

2. Conduct Thorough Research and Vetting

Investing time in researching potential suppliers’ reputations, certifications, and production capabilities is crucial. Reviewing their past performance, visiting manufacturing facilities, and evaluating product samples or quality reports will help identify a supplier capable of consistently delivering high-quality products.

3. Encourage Collaboration and Co-Development

View your supplier relationship as a strategic partnership. Share feedback, collaborate on product development, and explore ways to enhance process efficiencies. This collaborative approach fosters mutual growth and helps both parties adapt to evolving industry demands.

Conclusion

Selecting the right SS pipe supplier is not merely about cost considerations; it involves evaluating quality, reliability, and a commitment to long-term excellence. Cangzhou Shenlong Pipe Manufacturing Co., Ltd., with its adherence to international standards and focus on customer satisfaction, stands out as a top contender in the SS pipe supplier market. Engaging with such a reliable partner ensures that you have access to high-quality stainless steel seamless pipes, specifically designed to perform under even the most demanding conditions.

By understanding the advantages of working with a certified supplier and acknowledging the risks associated with non-compliance, businesses can make informed decisions that protect both their operations and reputations. Developing a long-term relationship with your supplier can pave the way for a robust, efficient supply chain that drives success and sustainability for years to come.